Whether it’s to regulate the temperature of food, medicine, or people, we’ll always need some form of cooling tech to survive. We tend to turn to air conditioning to solve these problems, but that has us stuck in a positive feedback loop that isn’t at all positive. Hot days are becoming hotter, and the demand for cooling is surging. How do we break the cycle? A team of researchers from the Massachusetts Institute of Technology have an idea: stack the same cooling techniques we’ve been using for thousands of years by harnessing the power of aerogel. No power, no emissions…no problem?

Before we get into MIT’s aerogel proposal, it’s important to discuss why curbing our AC addiction necessary. It’s because the way things are going, we probably shouldn’t be keeping our cool about how we keep ourselves cool. According to the Clean Cooling Collaborative, 20% of the world’s electricity is spent powering air conditioning and electric fans, and as temperatures intensify, usage is increasing. At this rate, the global number of AC units is projected to triple by 2050.1 The International Energy Agency reports that last year in particular saw cooling demand account for about 16% of all energy used in buildings worldwide — about 2,000 TWh.2

The problem isn’t just a matter of energy use, either. Air conditioning is a major contributor to CO2 emissions. The indirect CO2 emissions from cooling buildings more than doubled between 1990 and 2021 — to about 1 Gt.2If that wasn’t bad enough, AC also releases hydrofluorocarbon refrigerants (HFCs), which pollute the atmosphere even more. And they’re thousands of times more potent as a greenhouse gas than CO2.3

That said, air conditioning isn’t our only option. People have been using natural methods of staying comfortable indoors for thousands of years. We can see them in historic buildings all over the world, from the “wind catcher” towers in the Middle East and North Africa to the courtyards in China and Spain — and the “sleeping porches” in the American South. These structures aren’t just for show. They’re examples of passive cooling: architectural elements that control both the loss and gain of heat.45

So, managing a building’s temperature without consuming electricity or producing carbon emissions is nothing new. But when it comes to modern alternatives to air conditioning, the passive cooling system presented by MIT researchers in September is unique for its three-pronged approach. The design combines “insulated cooling with evaporation and radiation” into one convenient package called ICER. It sounds a bit like a frozen drink maker, but it’s more like a solar panel that uses the sun’s rays to produce cooling rather than energy.6

Let’s break down what that all means. To start, it’s important to remember that heat is our literal fair weather friend. It leaves when we need it in the winter, and intrudes when we want to avoid it in the summer. The good news: even though we can’t change the ways of an unreliable person, we can get around the way heat behaves with the power of thermodynamics.

Here’s how ICER does that. First, the “IC” is for insulated cooling. Generally speaking, insulation slows down the flow of heat from warmer areas to colder ones.7 As for “E,” evaporative cooling is the process of water lowering the temperature of a surface when it absorbs enough heat to change from liquid to gas, which we experience whenever we sweat.8

Lastly, “R”: radiative cooling is the loss of heat through thermal radiation, like when the Earth radiates heat out into space.9 This is what causes the chill we feel on cloudless nights, and it’s also how the people of Iran and India managed to make ice long before we could pop a tray into the freezer.10

In the context of reducing our reliance upon air conditioning, there’s promising developments on the use of radiative sky cooling to effectively shoot heat into space.11 I talked about how radiative cooling is being implemented in a previous video. It ‘s pretty cool. The MIT researchers behind ICER, though, do note that high-performance radiative cooling is typically limited to specific climate conditions.6

So now that we know the principles ICER operates on, how does it work? Well, one important aspect to that is what NASA calls, “one of the finest insulation materials available.”

You can think of it like an open-face sandwich. On the top is a layer of aerogel. Aerogel is basically what you get when you put a gelatin mold into a dehydrator (assuming you like the taste of plastic). Normally, doing that would just reduce your dessert to the powder you started with. The magic of aerogel is that it retains its shape even after its initial gel form loses all its moisture. The result is a solid but extremely light chunk of what NASA calls “one of the finest insulation materials available.”12

This is because aerogel is like a sponge, but with pores too tiny for the human eye to see. They make up 95% of aerogel’s volume, giving it a very low density.12These pores are smaller than human hair; about the same size as air molecules. Air has low thermal conductivity, meaning that it’s difficult for heat to pass through it.13 So, as a result of all these factors, air doesn’t have much space to flow freely through aerogel, making it very effective in thermal insulation — effective enough to use while exploring the cold void of space.14 Speaking of space, infrared radiation passes right through aerogel. That’s why ICER’s top layer can both insulate and allow for radiative cooling.15

Hydrogel is the next layer of the ICER sandwich. As the name implies, it’s the wet sponge to aerogel’s dry sponge: full of water instead of air. This water is the singular resource that ICER consumes. As it evaporates over time, it rises past the aerogel and out into the open, taking heat with it.15

When the hydrogel eventually dries out, recharging the ICER is simple: All it needs is someone to “just add water.” The researchers estimate that the setup can continue to function unattended for more than 10 days in most cases, or even over a month on the U.S.’s west coast. In hot, arid regions like Las Vegas and Phoenix, a single “charge cycle” can last about four days.6

Beneath the hydrogel lies ICER’s third and final layer, which is its mirror-like base. It reflects sunlight back through the layers above it, preventing the device’s materials from heating up. ICER’s aerogel is highly reflective, too, providing even more resistance against the sun’s heat.15

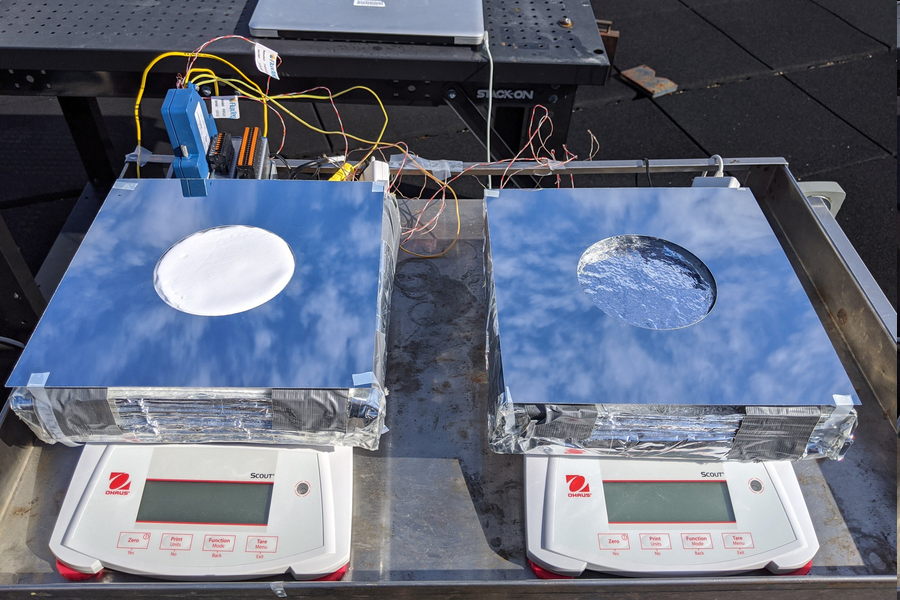

So far, ICER has only been tested on a small, 10 cm-wide scale, on top of a MIT building’s roof. However, the results were significant. The researchers reported that even under poor weather conditions, ICER’s capabilities represented a 300% improvement upon a radiative cooler. This amounted to ICER reaching 9.3 C below the ambient temperature under direct sunlight.6 16

Beyond its potential as a standalone cooling system, ICER could also be used in retrofitting existing air conditioners to improve their efficiency. Its inventors reference a 2017 Stanford University study that used radiative cooling panels to lower the temperature of running water. Using a simulation, Stanford researchers estimated that these panels could reduce the electricity consumption of an office building’s AC system by 21%17The MIT team predicts that ICER could save even more energy when integrated in a similar way.6This means that ICER might not necessarily need to replace an air conditioner, allowing us to work with what we’ve got. Meaning this could be an additive solution instead of a replacement.

ICER could also make a big impact on the way that we store food. One possible application is the preservation of fruit and vegetable crops on off-grid farms, no energy necessary. The researchers calculated that cooling food containers with ICER could extend the shelf life of produce by about 40% in humid areas and over 200% in drier ones. Especially in regions where traditional cooling systems are restricted by a lack of water or energy, ICER could theoretically prolong the shelf life of food when it would otherwise spoil.6It would be like having a cooler that cools itself.

But don’t throw your ice packs out just yet. Manufacturing polyethylene aerogel, or PEA, is unfortunately more complicated than sticking wobbly jelly into a drier. It’s a delicate operation that requires slowly removing solvents without compromising the structure of the gel. This is accomplished through critical point drying (CPD), which uses expensive special equipment. And as the researchers note, the CPD process isn’t yet scalable. Long story short, producing the aerogel that the ICER depends on is not cheap.15

But there’s still room for optimism. ICER’s aerogel component is the only one that isn’t freely available right now, but that might change as aerogel becomes more popular as a material for tech like supercapacitors and batteries.1819In the meantime, the MIT team is seeking out a viable way to cut down on costs. This could look like using freeze drying rather than CPD during production or swapping the PEA with a different kind of insulation altogether.15

In fact, we already know this is feasible. Researchers from Nanjing Forestry University in China and the University of Applied Sciences and Arts in Germany have also designed an aerogel-based passive cooler that blends radiative cooling and thermal insulation. Like ICER, it reflects sunlight, releases absorbed heat, and provides thermal insulation without any electricity.20The difference is that their aerogel is composed of cellulose nanocrystals and just so happens to be made using freeze drying in a process that can be scaled up.21

How does cellulose nanocrystal aerogel, or CNC, compare with PEA? Well, hopefully all this talk about jelly and sandwiches hasn’t gotten you too hungry, because here’s another food analogy. Marshmallows are a lot like aerogel: they’re made of gelatin, and they’re full of air. When marshmallows are cooked in a microwave, they inflate.22 PEA poofs up in a similar way as it’s made. In both cases, you end up with a big, fluffy solid full of trapped air, but you can’t do much to change its shape.

CNC is another story. It’s more like a soft serve ice cream cone, which you carefully turn to form its iconic twisted look. When producing CNC, scientists have a similar level of control over its structure as they direct the bonding of compounds that make it up. Like other types of aerogel, CNC has low thermal conductivity. However, gel-based networks of chemicals tend to be brittle, and cellulose nanocrystals are more robust. The CNC created for this particular study is also white and highly reflective.23It doesn’t hurt that cellulose is the most abundant biopolymer on earth, either.24

But did the cellulose aerogel perform as well? Turns out, the results published by the joint research team in May are very similar to ICER’s. To refresh your memory, ICER’s cooling was powerful enough to reach 9.3 C below the ambient temperature under direct sunlight.6The CNC-based cooler managed a drop of 9.2 C under direct sunlight and roughly 7.4 C in what the researchers call “hot, moist, and fickle” weather. And using modeling, the researchers estimated that their CNC cooler could reduce energy consumption in China-based buildings by about 35%.20

Aerogel is clearly a valuable resource in the realm of thermal insulation. But how does it compare against existing insulating materials in the real world? In a study published in September, a group of researchers from universities in China and Australia put their own formula to the test. Called anisotropic cooling aerogel, or ACA, it’s produced with freeze drying like CNC. What makes ACA’s development different, though, is that it’s inspired by 3D printing. The researchers built their aerogel panels block by block the same way a 3D printer builds an object in layers. This provided them with enough precision to keep the dimensions of the gel’s pores “aligned” and consistent in their dimensions.25

As for what “anisotropic” means and why it matters, most materials are either isotropic or anisotropic. If something is isotropic, its properties are even and identical throughout, regardless of the direction you measure it — nice and predictable, like bulk glass and metals. Otherwise, a material is anisotropic, meaning that its properties aren’t even or identical. Wood is a classic example. It’s stronger along its lines or “grain” than against it.26According to the researchers, anisotropic aerogels with highly aligned pores act as better insulators than isotropic ones, so it’s worth finding ways to produce them.25

And the ACA did deliver. When the team placed the gel on a hot plate heated to 90 C, its top surface eventually remained steady at a temperature of about 41 C. By comparison, two existing insulation products, EPS foam and silica aerogel, became 6 and 10 degrees C hotter than the ACA, respectively.25

In another series of tests, the researchers measured the ACA’s thermal insulation capacity on a hot and humid day in Hong Kong. Under direct sunlight, the ACA panel maintained a lower interior temperature than four other insulation materials: brick, glass, EPS foam, and silica aerogel. The ACA also demonstrated passive cooling with a drop of 6.1 C below ambient temperature.25 27

These experiments offer an exciting look into aerogel’s capacity for passive cooling. Even so, it’ll be some time before mass production of aerogel coolers is practical. In most cases, aerogel panels can be as much as 10 times more expensive than traditional insulation materials, whether they’re composed of silica or cellulose.24Aside from cost, the majority of testing has only been done on a lab scale.

That’s not to say aerogel is lightyears away from existing in our homes and workspaces. Its insulating properties are also useful in another essential part of architecture: windows. Poorly insulated windows can be more wasteful than you might think. According to MIT, each winter, windows across the U.S. lose enough energy to power over 50 million homes.28

To address this problem, the U.S. government’s Advanced Research Projects Agency-Energy (ARPA-E) began funding the production of materials that improve the energy efficiency of windows in a program launched in 2016.29The 14 teams in the Single-Pane Highly Insulating Efficient Lucid Designs or SHIELD program are developing products to apply to window panes and new window pane designs for retrofitting. Of these 14, four projects involve aerogel.30 And in 2019, MIT announced its success at fabricating a transparent form of silica aerogel. The research team estimated that a double-pane window with its air gap replaced by its aerogel panel would be 40% more insulating than traditional ones.28

Aerogel-based insulation has already left the lab. At this point, there’s a couple companies that sell windows incorporating aerogel into their construction or aerogel-based glazing that can be applied to windows and glass roofs. We’re long past wondering whether passive cooling with aerogel is possible. The hurdle at hand is eliminating barriers to widespread use.

- The cooling challenge at-a-glance ↩︎

- Space Cooling ↩︎

- Hydrofluorocarbons (HFCs) ↩︎

- The ancient Persian way to keep cool ↩︎

- Moving Forward by Looking Back: How Pre-Industrial Architectural Techniques Can Help Decrease Our Energy Consumption ↩︎

- Significantly enhanced sub-ambient passive cooling enabled by evaporation, radiation, and insulation ↩︎

- Insulation ↩︎

- What is Evaporative Cooling? ↩︎

- Radiant heat ↩︎

- Radiative cooling ↩︎

- Radiative sky cooling: Fundamental principles, materials, and applications ↩︎

- Aerogels: Thinner, Lighter, Stronger ↩︎

- Thermal conductivity ↩︎

- Aerogel: Remarkable Insulating Material of the Future ↩︎

- Passive cooling system could benefit off-grid locations ↩︎

- Significantly enhanced sub-ambient passive cooling enabled by evaporation, radiation, and insulation ↩︎

- Sub-ambient non-evaporative fluid cooling with the sky ↩︎

- Carbon aerogel based materials for secondary batteries ↩︎

- 3D Printed Graphene Aerogel Offers Highest-Ever Capacitance for a Supercapacitor ↩︎

- Dynamically Tunable All-Weather Daytime Cellulose Aerogel Radiative Supercooler for Energy-Saving Building ↩︎

- Cellulose-Based Passive-Cooling Aerogel for Buildings ↩︎

- Puffing Up Marshmallows ↩︎

- Novel cellulose aerogel radiative coolers for building applications ↩︎

- Cellulose Aerogels for Thermal Insulation in Buildings: Trends and Challenges ↩︎

- Scalable anisotropic cooling aerogels by additive freeze-casting ↩︎

- Isotropy vs Anisotropy ↩︎

- Supplementary Information ↩︎

- Making a remarkable material even better ↩︎

- Single-Pane Highly Insulating Efficient Lucid Designs ↩︎

- SHIELD Project Descriptions ↩︎

Comments