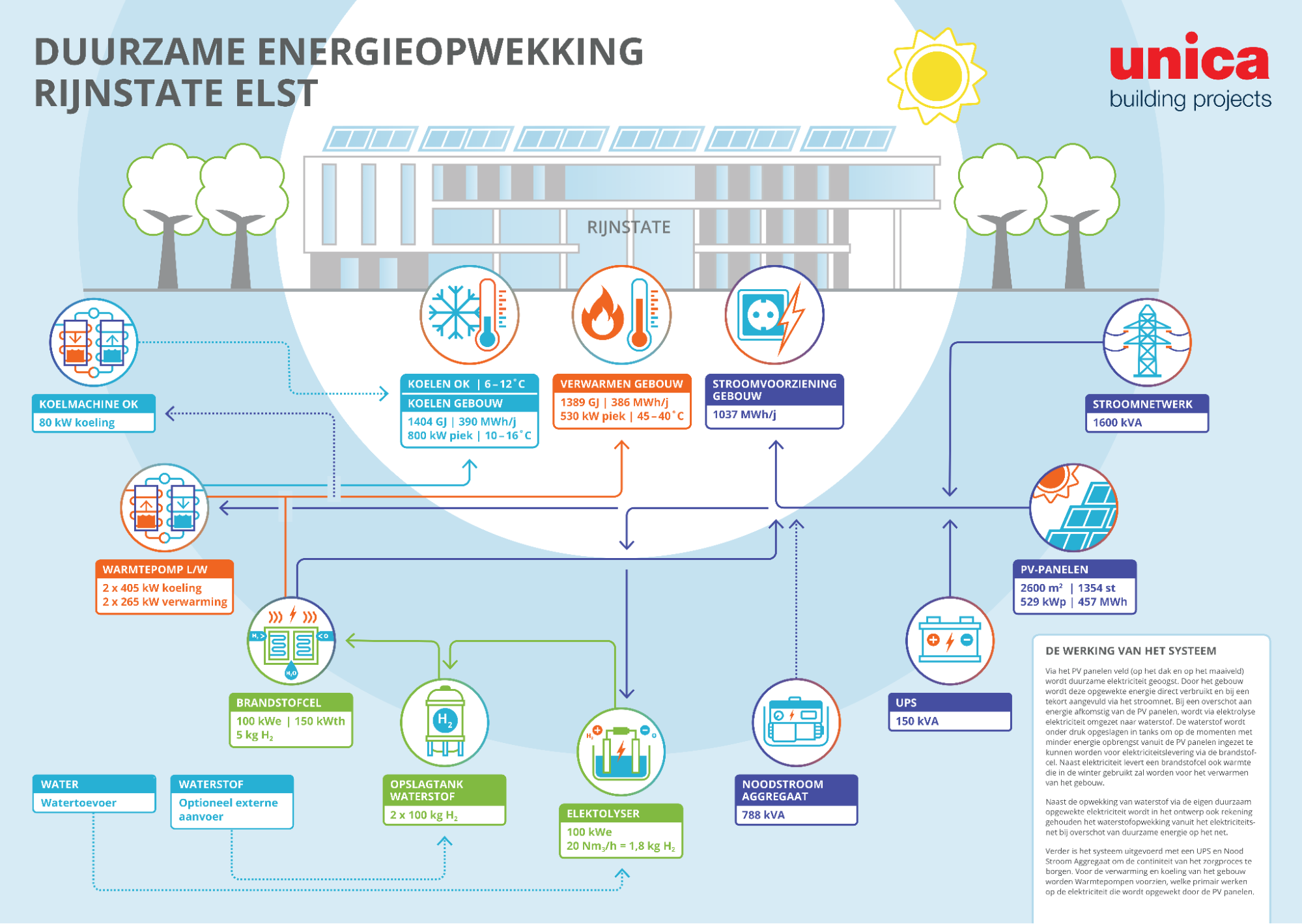

In the summer of 2023, the Rijnstate hospital of Elst, The Netherlands opened its doors. What makes this particular campus interesting is how it generates its energy. Heat pumps, PV panels, and an electrolyzer all work in concert to maintain a constant supply of power. The building collects energy from over 1,300 solar panels located on both the roof and the ground floor. When there’s a surplus of solar, that energy goes toward electrolysis, the splitting action that produces hydrogen. This then allows for hydrogen fuel cells to kick in as a form of reserve power when the sunnier supplies are low.123

The Rijnstate isn’t the only hospital that integrated hydrogen into its energy generation this year. Just recently, the Viamed San José Hospital located in Murcia, Spain, installed a system that involves powering the creation of hydrogen through its 289 solar panels. The resulting hydrogen feeds into a boiler for space heating. Meanwhile, the oxygen produced as a byproduct of the electrolysis is then repurposed as a critical resource for medical procedures.45

That’s insanely cool. Those hospitals are good examples of how green hydrogen is already getting used today, but it’s far from widespread. Energy efficiency, cost, and the difficulty of transporting and storing hydrogen are the main issues pushing back on hydrogen adoption. But we saw some major steps forward for producing hydrogen this year, like one of the cutting-edge hydrogen technologies I’ve covered in the past: Hysata’s groundbreaking electrolyzer. There’s some news to share there. Hydrogen is already making an impact in places like those hospitals, but how can new hydrogen tech help address this tiny powerhouse’s big challenges?

You can find hydrogen pretty much everywhere in the universe. It’s in full display when you look up at the sun and stars.6 It helps keep the pH of our blood in check.7 It supports agriculture through the production of ammonia.8 There’s even evidence that it could be used to fight cancer.9

Hydrogen-based energy is expanding into more and more fields — including healthcare, transportation, and heating, to name a few. Hospitals, data centers, trucks, boats, buses, boilers…you name it, somebody’s out there trying to power it with hydrogen as we speak.

There are some downsides to that, which I’ll get to in a bit … but first there’s some interesting updates on making hydrogen cleaner and cheaper from the Land Down Under. It’s here that I’d like to thank one of my Patrons, Jim, for faithfully keeping me updated on Australia’s hydrogen news.

A while back, I covered a new form of electrolyzer by the Australian company Hysata. Its design is really promising, with an efficiency rating jumping from about 75% to a whopping 95%. As the company says on its website, this translates into 25% less electricity lost as heat compared to the average electrolyzer.10 I broke down how the research team accomplished this in my previous video, and the process of how the electrolyzer works is also outlined in depth in a Nature Communications study published in March 2022.11

But the main gist of it is this: they’re using bubbles. Remember, electrolysis converts water into hydrogen and oxygen. Bubbles in the electrolyzer’s electrolyte fluid are non-conducting, and when they build up on the electrodes, it’s blocking parts of the electrode and hindering the process, reducing the efficiency. Hysata’s capillary-fed electrolyzer uses a reservoir at the bottom of the cell which keeps the electrolyte away and out of contact with both the anode and the cathode until it’s drawn through a porous separator. This is oversimplified, but the result: the electrolyte keeps direct contact, but only on one side, and the gasses are still produced without that annoying bubbling action that just gets in the way. Since water isn’t being drawn to the side with the electrode, the other side can keep releasing gas unhindered. As water is electrolyzed out of the separator, the capillary action naturally draws up more water to replace it, keeping everything running smoothly.

As that Nature study explains, green hydrogen lags behind fossil fuels because of its high capital expenditure and operating costs. Hysata targeted poor electrolysis efficiency because it’s the largest contributor to green hydrogen’s levelized cost of energy (LCOE). The ultimate goal: make green hydrogen cost-competitive.11 The company claims to not only have done just that, but to also drop the amount of electricity wasted through heat by 10 times and the quantity of liquid needed to pump through the system by 20 times.12 This all translates into significantly lower costs — and remember that money has so far been green hydrogen’s biggest barrier. Discounting hydrogen for a lack of efficiency alone isn’t the reason hydrogen will fail … it’s the money.

And it would seem that things are moving smoothly for Hysata. In August, the company opened a manufacturing plant in Port Kembla, Australia, to ramp up it’s electrolyzer commercialization. According to CEO Paul Barrett, these units are scheduled for delivery in 2025, with the company to “ramp up rapidly to giga scale capacity thereafter.”13

That’s just one example of how green hydrogen is improving in Australia. There’s also Sparc Hydrogen, a collaboration between Sparc Technologies, the University of Adelaide, Flinders University, and Fortescue Future Industries.14 Unlike typical setups, Sparc’s hydrogen production method doesn’t require an electrolyzer or electricity pulled from renewable energy infrastructure. Instead, it’s based on photocatalytic water splitting, or PWS.

Photocatalysts are any material that alters the rates of chemical reactions when exposed to light.15 Basically, Sparc Hydrogen’s approach is to use a reactor to combine solar energy with a photocatalyst to split water into hydrogen and oxygen.16 This is way oversimplified, but the basic process that light optically excites a semiconductor, which means having negative electrons floating around with positive holes. These rip the water apart into hydrogen and oxygen. A bad analogy would be double stuff oreos … hang with me here … you have two black cookies represetning two hydrogens and then the cream is oxygen. You are the photocatlytic water splitter when you tear the cookies apart. You’re left with two separate hydrogen molecules (the cookies) and yummy cream ready to eat. When you combine the two cleaned off cookie portions back together you get H2. Yes, that’s a stretch … but a tasty one.

That’s why PWS is also referred to as “direct solar to hydrogen” tech.17 The company claims that its patent pending reactor has multiple advantages, including reduced photocatalyst use, a modular design, and the ability to capture and reuse excess heat.17

Sparc Hydrogen acknowledges that PWS isn’t new. In fact, it’s been studied for over 50 years. There was landmark research using semiconductors to split water with light energy back in 1972.18 The difficulty, of course, has been bringing this concept to scale. It turns out that it’s relatively easy to do without losing efficiency…but high enough efficiencies haven’t been met in the first place…yet. A 2023 PWS overview identified the economic viability sweet spot as a 5 to 10% conversion efficiency rate, which are numbers the U.S. Department of Energy proposed. However, at the time of the study’s writing, the highest solar-to-hydrogen energy conversion value ever accomplished was a measly (approximate) 1%.18 It is important to note that this small efficiency is supposed to be small. A typical solar panel has a theoretical maximum efficiency around 30%. PWC is like a percent of a percent, so don’t get too hung up on the small efficiency. The key is how much you get out of the process … and researchers might have spoken a little too soon. A team from the University of Michigan just managed to reach an impressive efficiency of 9.2% with pure water and an indium gallium nitride photocatalyst earlier this year.19

But in Sparc Hydrogen’s case, it’s already on its way to commercialization. In June, it finished polishing its reactor design and began prototype construction. It also received a high-powered solar simulator — which is exactly what it sounds like — from the United States to continue work in the lab.20 With funding from CSIRO, Australia’s national science agency, the company began testing in September. The reactor is now sitting on top of the solar tower at the CSIRO Energy Centre in Newcastle, Australia.21 Sparc has also received a grant through Australia’s Economic Accelerator program to keep up its momentum. And so far, the company says the reactor has performed well through two bouts of testing.22

These are by no means the only viable ways to generate green hydrogen. Companies working to convert hydrogen sulfide into hydrogen and sulfur, like RedShift Energy and Thiozen, are cropping up.2324 There’s also initiatives to develop methods of creating hydrogen out of waste products, from paper to plastic.2526

Okay, so producing hydrogen is improving in interesting ways, but why is that important? Well, hydrogen has a lot of issues. We’ve discussed hydrogen a couple times on this channel before, so I won’t bog you down with the basics. Instead, I’ll direct you toward my previous videos, and also distill what’s what down to three major points: the good, the bad, and the ugly.

The good thing about hydrogen is that it’s a versatile form of energy storage, and when it’s created using renewable generation, the goal is to come out with no harmful byproducts. That means no waste and no emissions. Is that necessarily happening? Definitely not half as much as it needs to right now, which leads me right into the bad.

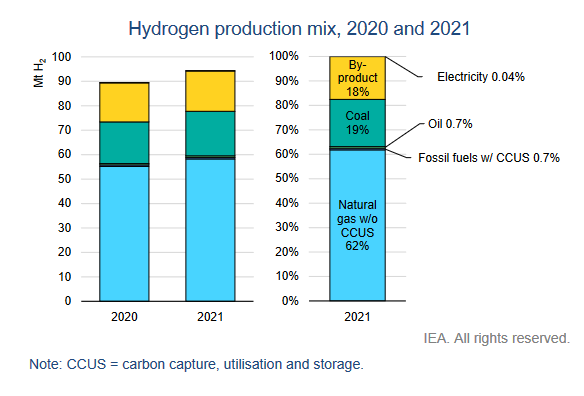

The bad thing about hydrogen is exactly that. You can’t catch hydrogen with a net or pan for it in a river and use it as-is. It may be everywhere, but it needs to be removed from something first, like water, biogas, or natural gas. That takes a lot of energy, and as it stands, the vast majority of hydrogen isn’t produced using the clean kind. In 2021, 62% of hydrogen production used natural gas.2728 To make matters worse, there’s also healthy, scientific skepticism about how “green” the process is even when it is based on renewables.29 Y’know, less than 1% of the time.27

Hydrogen is also very difficult to store because its molecules are just so small. They like to pretend they’re Houdini and escape the cracks and crevices of pipes and storage vessels. It is possible to safely engineer against that, but it takes extra effort and care.

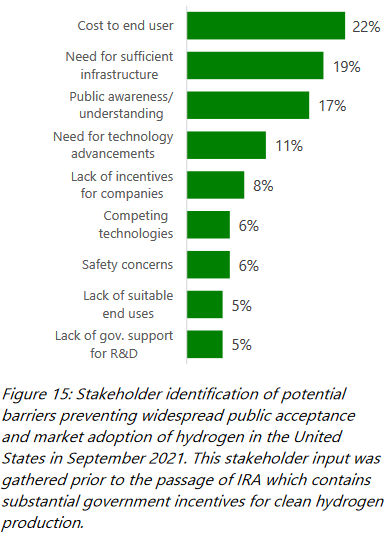

As for when an invisible gas becomes _ugly_…hydrogen tends to lose its appeal when we take a look at the price tag, pretty much like any emerging technology. This was made pretty explicit during the U.S. Department of Energy’s 2021 Hydrogen Shot Summit, which held an audience of over 3,000 stakeholders representing 34 countries. When asked what kind of obstacles were preventing widespread adoption of hydrogen tech, they pointed to cost more than anything else.

However, it’s important to note that this was before the passage of the US Inflation Reduction Act, which incentivizes clean energy production of all kinds, including green hydrogen.30 And though water-based (rather than natural-gas-based) electrolysis made up only a tiny fraction of all hydrogen production in 2021, but its usage did jump by 20% from 2020. As the IEA says, “this reflects increasing deployment of water electrolysers.”27 And we already know that at least in Australia, this trend is continuing.

This isn’t an extensive look at all of hydrogen’s downsides, or its possible use cases. But over the past few years my opinion on hydrogen has been shifting. It’s definitely not the end all be all energy solution that many promised for so long. At the same time, it’s also not a fool’s errand. There are specific use cases where hydrogen can do really great things, like when implemented in local energy storage solutions that allow you to produce, store, and convert back into electricity onsite…just take a look at the Rijnstate and Viamed San José hospitals. It goes to show that there’s plenty of room for hydrogen to make a difference in these kinds of facilities alone.31 With that in mind, continued research and development into hydrogen production and use makes a lot of sense to me.

- Rijnstate Elst is open! ↩︎

- Rijnstate Unveils Europe’s First Climate Neutral Hospital Powered by Hydrogen and Solar Energy ↩︎

- Rijnstate: complexe showcase van duurzaamheid en innovatie ↩︎

- LinkedIn Post by Andrea Manini, Head of Hydrogen & Fuel cell program BDR Thermea Group ↩︎

- Viamed Salud instala la primera planta de producción de Hidrógeno verde en un centro hospitalario en Europa ↩︎

- Hydrogen explained ↩︎

- An introduction to acid-base balance in health and disease ↩︎

- Hydrogen ↩︎

- A Systematic Review of Molecular Hydrogen Therapy in Cancer Management ↩︎

- Hysata – Our Technology ↩︎

- A high-performance capillary-fed electrolysis cell promises more cost-competitive renewable hydrogen ↩︎

- Hysata delivers the step-change needed in electrolysis ↩︎

- Hysata opens new electrolyser manufacturing facility in Port Kembla with $23m vote of confidence from Australian and Queensland Governments ↩︎

- Sparc Hydrogen – Our partners ↩︎

- Photocatalysis ↩︎

- Sparc Green Hydrogen ↩︎

- Sparc Hydrogen – Technology ↩︎

- A perspective on two pathways of photocatalytic water splitting and their practical application systems ↩︎

- Solar-to-hydrogen efficiency of more than 9% in photocatalytic water splitting ↩︎

- SPARC June 2023 Quarterly Activities Report ↩︎

- Tests begin on Fortescue-backed, concentrated solar hydrogen technology ↩︎

- Sparc pushes ahead with PWS plans for green hydrogen production ↩︎

- Using Plasma Energy To Turn Waste Into Value ↩︎

- A new process to generate low cost and low emission hydrogen from sour gases ↩︎

- A critical review on the principles, applications, and challenges of waste-to-hydrogen technologies ↩︎

- A shocking way to produce hydrogen from plastic waste ↩︎

- Global Hydrogen Review 2022 ↩︎

- EIA – Naphtha ↩︎

- Life-cycle greenhouse gas emissions and net energy assessment of large-scale hydrogen production via electrolysis and solar PV ↩︎

- U.S. National Clean Hydrogen Strategy and Roadmap ↩︎

- Health Care Pollution And Public Health Damage In The United States: An Update ↩︎

Comments