When it comes to heating and cooling our homes or producing hot water, heat pumps are proving themselves to be one of the most energy efficient ways to go. However, there’s a category of material that could be used to efficiently produce hot water, or to reduce your heating and cooling needs in your home or business. Phase change materials (PCM) have high energy storage properties, can be easy to install, and don’t take up a lot of space. Are phase change materials a good option for our homes? Let’s see if we can come to a decision on this.

Keeping our homes comfortable with conventional HVAC systems requires a large amount of energy. In 2020, heating and cooling homes in the EU accounted for 62.8% of energy consumption in the residential sector. Heating water accounted for an additional 15.1%.1 In the same year here in the U.S., heating and cooling accounted for 46% of energy consumption by residential and commercial buildings.2 The main energy source for heating is natural gas at about 46%, followed by electricity at 40%, propane at 4%, and fuel oil or kerosene at 4%. 3 The numbers for hot water are very similar.3 As a result, Americans spends $73 billion on heating our homes.4

These traditional heating systems consume a high amount of energy and produce tons of greenhouse gas emissions, but what if there was a sustainable and economical technology? I looked at one greener alternative in my heat pump video, but there’s another technology that caught my eye. Phase change materials may be another good option. Before we dive into the technologies that are currently available, let’s take a step back to understand the main principles behind them.

The basic concept of a PCM material is something you’re already very familiar with … and if you’re not, I’m very concerned … and that’s water. When water freezes, it changes phase from a liquid to a solid becoming ice. When ice melts, it changes phase back into a liquid state. Each of these phase transformations either absorbs or releases heat, based on the material’s heat (or enthalpy) of formation. PCM’s are no exception, absorbing or releasing heat during these phase transformations.

In a nutshell, PCM are substances that absorb and release large amounts of “latent” heat when they change their physical state (going between solid and liquid states). For instance, during the day a phase change material might melt because it absorbs solar heat. At night, the material releases the heat and becomes solid again.5 6 In the end this is all about storing energy as heat and not electricity. Paraffin, sodium-acetate, and hydrated salts are the most commonly studied and used materials for commercial phase change materials.7

So why is this important? Well, the thermal performance of a wide variety of products could be improved by taking advantage of PCM’s key benefit: absorbing and releasing large amounts of heat in a controlled way. Some of these products are available for your home right now. Let’s start with hot water. You could convert excess electrical energy from renewable sources into heat and use PCMs as short term heat storage … essentially, it’s a heat battery.

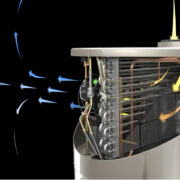

One good example of this comes from the Scottish company Sunamp, which has developed a product containing a heat exchanger and phase change cells meant for hot water, called the Thermino. Their products are essentially batteries that store heat instead of electricity, which means this acts a lot like a tankless water heater from a user’s point of view … without the flames. Sunamp’s system is compatible with a wide choice of energy sources, including heat pumps, solar PV, and boilers, which are what add heat into the system to be stored into the phase change cells. The material in the cell turns from a solid to a liquid as they store the heat. When you turn on the water in the kitchen or bathroom, cold water flows into the heat exchanger, transferring the stored heat from the phase change cells into the water, which causes the gel in the cells to solidify as it cools. As I mentioned, it’s very similar to a tankless water heater because it’s heating at the time of use. It’s not very efficient to hold 40 gallons of water at a set temperature, like in a traditional water heater tank.8

This hot water battery is 4 times more compact than a traditional hot water tank and has far less heat loss. According to the company, the hot water battery can save up to 1,000 kWh a year. However, there are some caveats, if Sunamp’s hot water battery will be powered by solar, you have to take into consideration where it’s installed.

Sunamp does have case studies for how the system performs. In one case, a 2-bedroom house with 2 people changed the conventional system over to the Sunamp system. They were heavy hot water users that took 2 baths in the morning and in the evenings. That’s a lot of baths … anyway, they saved 59% in energy use and 56% in cash, which was about £602.17 ($725) per year.9

For a cost comparison there’s some data from the UK. The Sunamp’s Thermino 150e with a heating power of 2.8kW and 15 L/min flow rate costs £1,945 plus VAT. Including installation, the price increases to £3,245 plus VAT. 10 On the flip side, a conventional water heater, such as the Electric Combi Boiler with a similar capacity of 3 kW and 12 L/min flow rate costs £2,370 including VAT. The total cost with installation and accessories ranges from £3,170 to £3,670.1112 When you add in the VAT, which I believe is about 5%, for Sunamp it’s a little bit more, but the benefits are seen overtime since a conventional water heater can lose about 1.3 kWh of heat per day while Sunamp’s only loses about 0.74 kWh heat per day – almost 50% less.13 That’s going to add up over time.

Another type of hot water battery that’s been developed is from MaREI (Science Foundation Ireland Research Center for Energy, Climate and Marine), which is a 300L hot water thermal energy storage tank with a PCM paraffin bed.14 The system can store solar energy for later use. The way the system works is that water flows across a solar water heater and then on to an encapsulated PCM-bed in a hot water thermal energy storage tank. During periods of higher solar irradiation, the hot water reaches the melting temperature of the solid PCM, which causes it to melt. When the solar irradiation is lower or non-existent, like in the afternoon or night, the water gets colder, which causes the PCM-bed to transfer heat to the water, maintaining a consistent water temperature. The group found promising results. For a single solar collector integrated with a PCM-bed in the hot water tank, hot water with a temperature of 60°C can be maintained for 7 hours of operation. However, this product was only tested at lab/pilot scale, but the results show the potential of integrating a PCM-bed and solar water heater.

PCMs aren’t just about heating water. They can also be used to supplement heating and cooling your home when combined with your HVAC system. A PCM can be applied as a thermal coating, so with this idea in mind, the company Phase Change Solutions (PCS) developed what they call BioPCM.15 One product that the company offers for residential thermal management is the ENRG Blanket. Their BioPCM is sandwiched between two rugged, multi-layer films (polymer and/or aluminum). The resulting “blanket” is tear-resistant, long-lasting, and is rated to maintain its thermal performance for over 100 years. The idea is to place it above drop ceilings, roofs or stapled to exposed wall studs in a retrofit or new construction. They also have a 2’x2’ rigid panel, called the ENRG Panel (I bet you couldn’t see that one coming).

When room temperatures increase to uncomfortable levels, the PCM absorbs “excess” heat, helping to cool the room and reduce the need for mechanical cooling. As the room’s temperature drops, the stored heat is released back to the room, helping to warm and maintain a comfortable temperature, like at night. This phase change process can help with temperature management for homes. Basically, smoothing out the temperature variation over the course of a day, which in turn reduces the demand on your HVAC system and energy consumption.

How much? Well, it’s been used in over 1,000 commercial buildings, so there’s a lot of information on the potential savings. It reduced HVAC power consumption by 25-35%, run time by 15-20%, and cycling frequency by 20-25% (depending on building type, orientation, age, location, and HVAC equipment make and age). For a building of 25,000 square feet, the ENRG Blanket can save up to 81,000 kWh of electricity, avoid 57 metric tons of CO2 emissions, and provide over $8,000 per year of energy savings. Again, that’s for a commercial building. At a cost of $4.50 per square foot, PCS says the return on investment takes less than four years.16. 17 18

The Texas-based company QE Platinum is manufacturing PCM insulation with the same principles as PCS’s ENRG Blanket. QE Platinum is a multi-layer film with a foil surface to supplement traditional insulation methods with PCM.19 This PCM lays on top of the existing insulation in your attic or on top of the suspended ceiling tiles. Once installed, QE Platinum will immediately begin increasing the thermal efficiency of the space it’s in, so you stay comfortable while your HVAC runs less. The benefits include a 20-year life expectancy, reduced energy consumption and carbon emissions. We’re talking about a potential of 20% energy savings.20

PCM’s can be made non-toxic, biodegradable, low or no flammability, and even made from bio-based sources, like QE Platinum’s PCM. When it comes to the insulation supplement PCM products, they also have the benefit of not needing electricity to function; during a blackout or a mechanical failure of your HVAC system, you’ll still get the benefits of the PCM.21 However, PCMs do have some drawbacks. The insulation supplement products typically only work well within a specific temperature range because they need enough of a temperature swing to charge and discharge the stored heat. On top of that, while some of these products can show a good return on investment, they’re more expensive up front than traditional home insulations. While typical insulation material such as rigid foam costs $0.25 to $1.40 per square foot (pandemic pricing aside), PCM insulators cost about $3.50 per square foot, so it’s 2.5 to 14 times more expensive than conventional home insulation. 2223 Another challenge for PCM adoption is the lack of awareness regarding the benefits of using these materials for energy storage, as well as government regulations and subsidies to make the technology more accessible. If you’d like to learn more about the ins and outs of these insulations, I’d strongly recommend checking out Belinda Carr’s video on them. She has an amazing YouTube channel about building science and products just like these.

There are a few technical challenges with the insulation PCMs. While different blends of material can yield different phase transition temperatures, there is still the concern that using a particular PCM means only setting your thermostat at one temperature. In other words, for the full energy savings to be realized, you shouldn’t adjust the thermostat, or else you will waste energy heating and cooling the thermal mass of the PCMs and their absorbing and releasing heat rather than heating or cooling the room effectively. 21

Finding the perfect temperature is not as simple as mixing different materials, either. One of my copy editors for these videos has a background in material science and he pointed out that phase diagrams that plot composition on one axis and temperature on another show where materials are solid, liquid, or in a pasty in-between phase. Eutectic compositions are compositions that transition from solid to liquid directly, and non-eutectic compositions go from solid, to a paste to a liquid. Each of these have their own thermal advantages and disadvantages, and can make it difficult to find the optimal composition for a specific transition temperature.

Another problem is that PCMs are heavier than traditional insulation. At first glance, this may not seem like a problem, but consider that they must be attached somehow, and, unlike regular insulation they can’t be simply stapled to the joists or studs haphazardly, as the PCM cells shouldn’t be punctured. Also, the PCM shouldn’t sag away from the wallboard, or it will lose effectiveness.21 Having said that, with proper installation and following the manufacturer’s guidelines, you can see impressive results.

PCM is a growing market, with expectations to grow from $477 million in 2021 to $1 billion by 2026.24 As for the price of the products themselves, we can expect to see these prices drop in the future as companies join the market, manufacturing scales up, and new research and advances are developed. As an example of that, the price of salt hydrate, which is used in some PCMs, has been dropping recently … and the use of Bio-based PCMs presents a less expensive alternative to paraffin-based PCMs.25

Obviously, your mileage will vary with all of this because it all depends on your specific needs and goals, as well as where you live. But it’s exciting to see more options like this hitting the market to make our homes more energy efficient. I’m currently building a new net zero home and would have loved to integrate something like Sunamp’s heat battery into my system, but it’s not available in my area yet and I’m already going to have a very efficient hot water setup linked into a ground source heat pump. There’s so many options and directions you can choose from when designing what works best for you. It can make your head spin … but stay tuned because I’ll be publishing a bunch of videos on my home build.

- Energy consumption in households ↩

- U.S. Annual Energy Outlook ↩

- Residential consumption survey ↩ ↩

- Home Energy Use ↩

- Phase change material ↩

- How PCM works? ↩

- Materials ↩

- Sunamp heat batteries ↩

- Sunamp: case of study ↩

- Sunamp’s intallation ↩

- Electric Boiler ↩

- Electric combi boiler technical features ↩

- Comparative with tanks ↩

- Hot water thermal energy storage tank ↩

- BioPCMM ↩

- ENRG Blanked ↩

- ENRG Blanket Model M-55 ↩

- ENRG Panel ↩

- QE Platinum ↩

- AIMCAL 2022 Product of the Year Award ↩

- Are PCM an effective solution? ↩ ↩ ↩

- How Much Does Rigid Foam Insulation Installation Cost? ↩

- Insulation that stores energy ↩

- Global phase change material

market ↩ - Phase Change Materials Market ↩

Comments