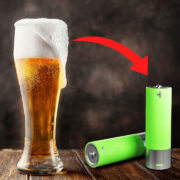

Among the many environmental crises that society must deal with over the coming decades, two stand out as particularly troublesome: plastic pollution and food waste. There may be a way to solve both problems at once: turning our rotting food into biodegradable, compostable plastic.

This would be no small feat, either. Consider the scale of our addiction to plastic: over the last two decades, plastic production has doubled to 460M tons and accounts for 3.4% of global greenhouse gas emissions. 1 Meanwhile, the global plastic recycling rate has dropped to a measly 5%. 2 Every year, 18 billion pounds of plastic end up in our oceans. 3

The news on global food waste is just as grim. One-third of all food produced for human consumption is lost globally. In industrialized countries, 40 percent of that loss comes at the retail and consumer levels. Food waste that rots in landfills, s accounts for around 6% of all global greenhouse gas emissions – which is around three times the emissions from the airline industry and, if we considered “food waste” a country, would be the world’s third largest emitter behind China (21%) and the United States (13%). 4

Turning our food waste into plastics would help to mitigate both crises, and it’s not as crazy of an idea as you might think.

Food waste plastics are a kind of alternative plastics known as bioplastics. Simply put, bioplastics are made from plants or other biological material instead of petroleum.

The last several decades have seen an abundance of bioplastics invented and used in lieu of conventional plastics. All of these products are created much in the same way as petroleum-based plastics: the raw material or feedstock is broken down into monomers, which are then chemically combined to form polymers. The polymers are then formed into tubes, sheets, films, wires, or pellets before being turned into their final products. 5

Historically, bioplastics have been made by extracting sugars from plants, such as sugarcane or corn. Thus, the advantages of bioplastics are twofold: they do not require fossil-fuel inputs to be manufactured, and they are largely biodegradable.

Food waste plastics offer even more advantages. By using food waste as the feedstock for plastic, the production process utilizes a resource that already exists. In other words, it doesn’t have to be grown. Using corn and sugarcane as inputs for bioplastic production has many costs. Water is needed to grow the crops. Fertilizers that keep them healthy can lead to pollution. The land they are grown on may have been diverted from food production. 6

What’s more, depending on the type of polymer used to make the bioplastic, it may require an industrial composting facility to heat it to a temperature at which it can be broken down by microbes. Certain bioplastics which leak out of end-of-life processing may end up in marine environments, where they will take decades to decompose and present many of the same hazards to marine life that petroleum-based plastics do. 7

Food waste plastic does not present any of these issues and, of course, also contributes to solving a major aforementioned problem: it removes rotting organic material from landfills that would have otherwise emitted greenhouse gases.

One company at the forefront of food waste plastic is Ontario-based Genecis Bioindustries. Genecis processes food waste that would otherwise be destined for landfills into a specific kind of plastic called Polyhydroxyalkanoates (PHAs). Other companies also create PHAs from sugar cane and corn, but Genecis has developed a novel technology to create the same plastic using food waste. 8

Like any plastic, Genecis food waste plastic can be used to create all kinds of products. Importantly, however, this specific kind of bioplastic does not take years or decades to break down. PHAs can decompose in terrestrial or marine environments in 12 months and can be processed by traditional composting. Any products that do end up in oceans can be safely eaten by wildlife and broken down into carbon dioxide and water. 9

We have a long way to go until bioplastics of any kind make up a significant percentage of all plastics circulating around the globe. The bioplastics industry, of which food waste plastics are only a slice, is valued at less than $8 billion.10 This is dwarfed by the total plastics market which reached over $600 billion in 2022. 11

Nonetheless, there is clearly a need for the world to begin making the transition away from conventional plastics. Bioplastics, and food waste plastics in particular, offer an intriguing solution.

Interested in seeing other innovative approaches to plastics? Check out our stories about turning fungus, algae, silk, and seaweed into plastic.

- “Plastic pollution is growing relentlessly as waste management and recycling fall short, says OECD” ↩

- “U.S. plastic recycling rate drops to close to 5% – report” ↩

- “Genecis: A Solution to Microplastics?” ↩

- “Food waste is responsible for 6% of global greenhouse gas emissions” ↩

- “Life in bio-plastic, it’s fantastic” ↩

- “What you need to know about plant-based plastics” ↩

- “What you need to know about plant-based plastics” ↩

- “Genecis Bioindustries: High Performance Bioplastics” ↩

- “Genecis Bioindustries: High Performance Bioplastics” ↩

- “Market value of bioplastics worldwide from 2018 to 2021, with a forecast for 2028” ↩

- “Market size value of plastics worldwide from 2021 to 2030” ↩

Comments