We’re always chasing better performing and more efficient solar panels to help power our renewable future, but no matter how efficient a panel is there are location-based impacts to performance. Tilt angle and orientation can either boost or decrease performance, and it’s hard to achieve optimum performance in all locations. Solutions like solar trackers can help to overcome some of these issues, but they’re usually not worth it in most cases. Instead of creating more efficient solar cells or tracking the sun, a research team at Stanford has boosted PV efficiency, even on cloudy days, by concentrating the light that reaches the solar cells without any moving parts. Is improving solar generation really that simple? Let’s see if we can come to a decision on this.

I’ve covered a lot of solar panel advancements over the past few years. In a previous video, I touched on solar panel efficiency breakthroughs from 2022. We ran through some of the more exciting updates, pros and cons of solar panels and my current take on it. The truth is that solar panels are efficient enough today to achieve many of the energy needs you probably have for your home. However, there are still several aspects that affect their power generation, and a couple of these are orientation and tilt angle. Solar panels require an optimal tilt angle and direction to capture the maximum amount of sunlight and ensure peak performance.

When it comes to orienting solar panels, geographic location plays a crucial role. If you live in the northern hemisphere, the ideal setup is to face your solar panels south. The reverse is true if you live in the southern hemisphere. For a better understanding of this, think about a home in the northern hemisphere with a horizontal roofline, so it has a roof facing both north and south. The north side of the building is basically shaded the whole day since the sun rises in the east and sets in the west, moving in arc towards the equator line. During the morning, the west is shaded and the east receives the sunlight. In the evening, the east is shaded and the west is exposed to the sun. That means the southern side of the house will be exposed to far more sunlight throughout the entire day. 1. If you face solar panels in any other direction you can expect to see significant power output losses. Homes that have solar panels facing east or west will produce around 15% less energy, while facing north will see losses of about 30%.23 On my house I have panels facing east and west because I don’t have a roof facing south, so my panels don’t see maximum output over the course of the day. I knew that going in, which is why I added as many panels as I could to try and make up for that.

The other important factor is the tilt angle, which is basically the vertical angle of your panels. Ideally, the sun’s rays should be perpendicular to the surface of your solar panel because it results in the highest level of solar production. 4 Typically, an ideal tilt angle for your solar panels will be equal to or close to the latitude of your home. The further north you go, the more your panels should be tilted.5. In this position, the solar panels will face the sun’s highest point in the sky in summer and its lowest point in winter. However, proper tilt angle varies with the season, and it reduces the power output of fixed solar panels.6 Again, if you’re getting solar panels installed on your home, this is all taken into account when a solar installer is factoring estimated solar production for your home.

For most U.S. property owners, the ideal angle for a solar panel installation is somewhere between 30 degrees and 45 degrees. 7 But, in real life PV installers face challenges in achieving the optimal angle. Residential systems generally have higher or lower tilt angles because they’re matching the roof pitch. Other issues such as available roof area, the minimal separation between rows of PV modules, space for a maintenance operation, avoiding panels shadowing each other, and dust deposition also can impact generation. 8

Researchers from the University of Oviedo put some numbers to the energy losses we’re talking about here. Tilt angle deviations of up to 10° in relation to the optimum tilt angle have less than 1% impact on the incoming solar irradiation. On the other hand, if the tilt angle deviations are in the order of 31° to 33°, the solar panel produces 10% less energy. 8.

For example, the best solar panel angle to satisfy both the winter and summer conditions in New York is 41º. If the panel tilt angle is instead near 30°, the average annual solar radiation will be 4.46 kWh/m² per day. However, if the angle is decreased to 5°, the solar radiation drops to 4.02 kWh/m² per day. It indicates that the estimated electricity production of a 5 kW system will reduce from 6,075 kWh to 5,438 kWh. These numbers mean that the solar panel with a tilt angle of 30° will save an Annual electric bill of $1,215 while the panels with 5° tilt will save $1,088.7

This is where solar tracking systems can boost PV generation throughout the year. A solar tracking system adjusts the solar tilt angle to be aligned with the sun as it moves across the sky. It uses sensors to capture the sun’s movement and a control system to drive electric motors that will constantly adjust the orientation and tilt of the solar array. 9 There are two types of tracking systems. Single-axis tracking systems tilt on one axis, vertically or horizontally tracking the sun throughout the day. Dual-axis tracking systems track both the horizontal and vertical movement of the sun. 10 A solar panel system with a single-axis solar tracker provides an energy increase of 10~30%. For example, a fixed 1.28 MW PV system in Melbourne, Australia, that produces 4,612.01 kWh/day would generate 5,783.71 kWh/day with a solar tracker. 11

Trackers work one of two ways, either by timer or by sensor, or some combination of the two. Timers can be programmed for a latitude and they will automatically point the solar panels in the direction where the maximum sunlight should occur for the date and time at that latitude. Photoelectric sensing can be used to find the “sweet spot” for the maximum solar energy. For a single axis tracker, a sensor is mounted above and another one below the axis. If one of these sensors sees more light, it activates a relay to a motor that moves the panel until the light is balanced between the two sensors.

Timers are relatively hasslefree, but are especially susceptible to clouds. Picture a pesky cloud that keeps getting in the way; the timer has no way to know this and continues to point right at the cloud. Photoelectric sensors, on the other hand, would see the imbalance, and point away from the projected optimal position, finding the true optimal position, which may be a few degrees from direct sunlight. The disadvantage to using photoelectric sensors is developing an algorithm that keeps the system from “chasing the sun” and constantly moving position, each movement uses power and reduces the efficiency overall.

The downside of using mechanical solar tracking systems is that they’re more expensive and tend to have higher installation and maintenance costs — more moving parts make them more likely to break and shut the system down for hours, or even days. Moreover, trackers are too heavy to be used on rooftops, so they’re usually installed using a ground-mounted system, which limits their use cases. 12

Let’s say you installed 15 ground mounted solar panels with a power rating of 300 watts each. The total cost of this system would be $14,625. If you want to include a solar tracker in this system, that would cost an additional $500 per solar module, adding up to a total cost from $22,125 for single axis or $29,625 for dual axis. The annual energy saving with those systems is around $1,430 and $1,540, which is only slightly more than the $1,100 savings with a fixed PV system. 13 On top of that, the operation and maintenance (O&M) costs for a one-axis tracker is $14/kW per year. Compare that to a fixed utility-scale PV system which has a price of $13/kW per year.14 So you can probably see why it’s generally viewed as not worth it to use solar trackers given the higher upfront cost when you can instead just add a few extra fixed panels to make up the production shortfall.

These downsides have motivated researchers to seek new technologies to increase solar production while keeping costs low. One technology that’s being explored is concentrated photovoltaics (CPV). For a quick overview, concentrating photovoltaic systems convert light energy into electrical energy in the same way conventional photovoltaic cells do. 15 The difference in the technologies is that CPV adds an optical system that concentrates sunlight onto a small high-efficiency conversion solar cell to obtain higher electrical power. 16 These kinds of systems are a bit like telescopes oriented towards the position of the sun, feeding the cell with concentrated light.

Currently, CPV technologies use lenses or mirrors to reflect and concentrate the sunlight. 17 I’ve already made a video on concentrated solar power using mirrors, so I’m just going to focus on CPV that uses lenses. These systems use an optical element that collects the sunlight and focuses it onto a tiny high efficiency solar cell, called a multi-junction solar cell, which converts solar power into electricity. The multi-junction solar cells are commonly composed of three solar cells connected in series. Essentially, each layer collects a different wavelength of light, so together they’re able to achieve a higher efficiency (sometimes around 40%) compared to a standard, single junction solar cell (usually around 20%).18 As the sunlight is concentrated and focused on this cell, the energy production is increased considerably.

CPV system designs have been developed into three categories. Low concentration where the magnification ratio is less than 10X, medium concentration is usually between 10X and 100X, and high concentration is somewhere between 100X and 1000X. In a nutshell, if you concentrate 10 or 100 times more light onto a properly designed CPV cell, you theoretically can produce more than 10 or 100 times the electricity.17

One example of a CPV system is the low concentration PV module from Zytech Solar. It provides a concentration level of 2.25X by adding mirrors to the sides and using prismatic lenses to concentrate the sunlight, which boosts energy production by 1.8 to 2X compared to a typical PV installation.19

One advantage of these types of solar systems is that they require less land area compared to conventional solar power to produce the same electricity output. However, this comes at a higher cost. Concentrated photovoltaic panels cost $0.80 to $1.10 per watt while traditional solar panels cost $0.70 per watt. 20 Another issue is maintenance with the addition of tracking and cooling systems. The annual operating and maintenance cost of CPV power plants located at Puertollano, Spain, ranges from 20 to 30 €/kW (the current values in USD are basically the same). 21

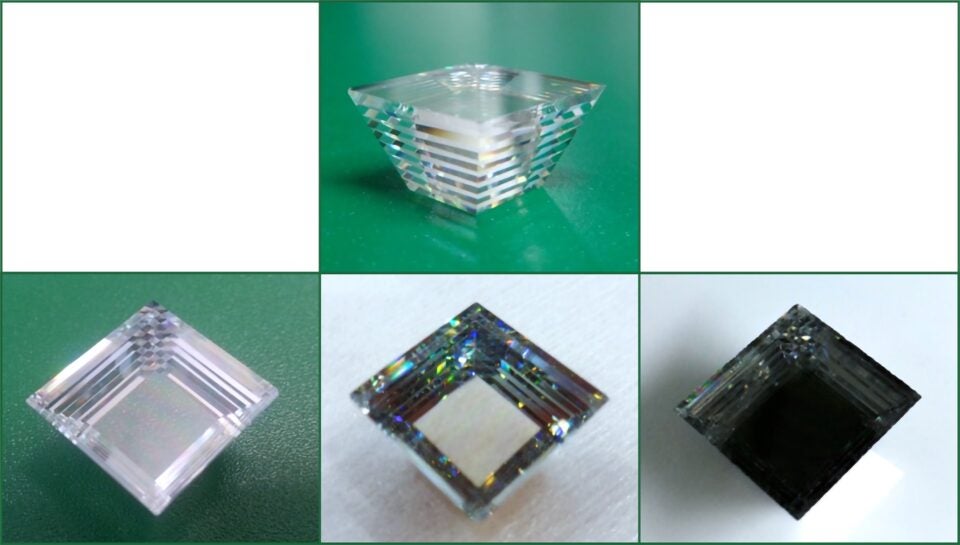

With this idea in mind, a group from Stanford University developed a non-tracking concentrator device, which has the benefit of improved power generation without any moving parts. Their new immersion graded index optic system is called AGILE, and was presented in the July issue of Microsystems & Nanoengineering journal. 22 It’s a device shaped like an upside down pyramid with the bottom point lopped off that captures sunlight regardless of the angle of incidence and concentrates it onto a small area. 22 23 The way it redirects sunlight from virtually any angle is from the interior, which has reflective sidewalls that funnel the light down to create a brighter output spot on the bottom.22.

Different stages of the graded index glass pyramid fabrication: when in optical contact with a solar cell, the pyramid at the final step (bottom right corner) absorbs and concentrates most of the incident light and appears dark. (Image credit: Nina Vaidya)

Robust, transparent, and inexpensive materials were critical to the success of AGILE’s design. 22. For the prototypes, the research team at Stanford layered together different glasses and polymers that bend light to different degrees, creating what’s known as a graded index material. The authors point out that AGILE can be fabricated using 3D printing and these common materials. This can simplify the manufacturing because it’s relatively easy to change the composition of the feedstock as the additive manufacturing progresses. You can slowly transition from material to material. This is sometimes called “functionally graded” or “functional gradient” manufacturing.

They tested two different prototypes and both prototypes demonstrated a 3x optical concentration and achieved a 90% efficiency in capturing light, so it’s not hard to imagine how big an impact this could have on existing solar panels. If you modified the existing top encapsulation layer that protects a solar panel with a layer of AGILE, you’d reduce the amount of solar cell area needed to produce energy. It would also help reduce the negative effects of tilt and orientation of the panel.22 24 The benefits of this system could potentially reduce manufacturing and installation costs while increasing solar production compared to traditional solar trackers and CPV systems. It’s basically like getting the benefits of tracking systems without the moving parts and maintenance issues.

The obvious negative is that AGILE is still at lab scale. However, according to the researchers, their solution presents reduced costs, design-flexibility, and scalable fabrication techniques to make implementation easier with common materials and 3D printing manufacturing. 22 25 There is evidence showing that optical devices made with 3D printing can maintain or exceed the surface quality of traditional techniques, which can make fabrication faster, scalable, and cheaper. 26

As we move towards a sustainable future, improvements in solar energy generation are essential. It’s not just about boosting performance no matter the cost, but finding new and clever ways to engineer around the problems we’re running into … in a cost effective and sustainable way. PV tracking systems already exist, but the added costs and challenges make them a more niche solution. Something like AGILE, however, could turn out to be a pretty large scale solution to boost solar production. We just have to be patient because there’s still a long road ahead to get this out of the lab.

Additional details:

- Details on AGILE: https://www.nature.com/articles/s41378-022-00377-z

- AGILE Patent: https://patents.google.com/patent/US9329308B2/en

- Dr. Nina Vaidya: https://www.linkedin.com/in/ninavaidya/

- Research group: https://twitter.com/VaidyaGroup

- Which direction must solar panels face, and what angle should they be tilted at? ↩

- What is the best direction for solar panels to face? ↩

- What Is The Best Angle And Orientation For Solar Panels? ↩

- Solar Panels must be in right angle ↩

- What Is The Best Angle And Orientation For Solar Panels? ↩

- The best tilt for solar panels ↩

- What’s the best orientation and angle for my solar panels? ↩ ↩

- Tilt and azimuth angles of photovoltaic systems ↩ ↩

- What is a solar tracker and is it worth the investment? ↩

- What Is a Solar Tracking System? ↩

- Static vs tracking solar ground mount systems ↩

- Solar trackers: everything you need to know ↩

- What is a solar tracker and is it worth the investment? ↩

- US solar maintenance costs plummet as tech gains multiply ↩

- Concentrated Photovoltaics ↩

- The Future of Solar Energy: High Concentrated Photovoltaic (CPV) Cells ↩

- What’s new in concentrating PV? ↩ ↩

- What is Concentrator Photovoltaic (CPV) Technology? – Benefits and Challenges ↩

- Concentrated Photovoltaics (Low and Medium) ↩

- Price of Solar Panels ↩

- Maintenance of CPV plants, how much does

it cost? ↩ - Immersion graded index optics: theory, design, and prototypes ↩ ↩ ↩ ↩ ↩ ↩

- Glass pyramid concentrator for solar cell applications ↩

- Optical concentrator could help solar arrays capture more light ↩

- AGILE – 3D Printing Patent ↩

- Optical devices 3D printing ↩

Comments