I’m in the process of building a new energy efficient, net zero modular home that’s being built in a factory. Why did I choose this path versus one of the many other sustainable and energy efficient methods like stick built passive homes, ICF, earthships, etc. (fill in your favorite technique)? There’s no one right way to do this, but I think the best way to walk through why I went the path I did is to show you how Unity Homes builds their houses. This may spur ideas for yourself. I had the chance to see my house’s wall panels getting built in the factory and to say it was cool would be an understatement. After seeing this, you might see why factory building energy efficient homes and buildings might be a good path for the future.

Before getting into the factory tour just a quick recap of what’s happening here. In my previous home build video I walked through the high level overview of what I’m doing and why. In short, I’m trying to build an energy efficient net zero home, which means a house that generates as much electricity as it uses over the course of a year. I’m a big fan of passive houses, but didn’t want to go through all of the logistical hurdles of getting actual passive house certification. That’s when I zeroed in on factory built modular homes that have proven they can hit that level of performance with some additional benefits. I’ll get to those in a bit, but at a high level here is how the process works.

In my case I’m working with the company, Unity Homes, which is an offshoot of the company, Bensonwood Homes. In principle the two companies share the same prefab, factory built methodology, but Bensonwood is on the full custom design, high end homes side of the spectrum. They do everything from homes to office buildings. Unity is the more affordable, modular approach side of things, which uses the same sustainable, and energy efficient principles. In fact, both Bensonwood and Unity projects are built in their facility in Keene, NH. And before I go on, I hate that I have to state this, but to head off the overly skeptical folks in the crowd, I have no business relationship with Unity or Bensonwood other than being a customer who paid full price for the home they’re building for me. That said, it’s a really cool company that’s the brainchild of Tedd Benson.

The way it works is that you select from one of five base models. From there you can actually customize it a fair amount to dial it into what you want and need out of the home. The benefit of this approach is to drive down costs.

“Unity is really completely focused on making high performance, high quality buildings more affordable and more accessible. And so, in the Unity constellation, we have developed five different platforms to standardize enough about the building that we can bring costs down in the design process, in the construction process.” -Tedd Benson

In our case we went with the Xyla model and customized the design. It’s kind of like lego blocks, so you can flip things around, add an additional module, and dial things in to what works for you. For my wife and I, we added a connector between the main house and an attached garage, which has my studio built off the back of it. There’s a whole bunch of reasons I did that for my studio, which I’ll get into in future videos. I was impressed with how much we were able to customize it within just the Xyla base plan. At this point is when the design transitions over to what they call virtual fabrication, which is probably one of the most important aspects of Unity’s system. It shouldn’t be a surprise that all of this is designed in CAD software, which is computer assisted design. However, Unity’s virtual fabrication process is a little more sophisticated.

“One of the key elements is that we actually build a digital twin of the building in the virtual world. And in that digital twin, everything is there. The infrastructure is there, for the mechanical systems, the foundation is there, right down to trim and other finish elements are in that virtual model.” -Tedd Benson

Everything is in this virtual model, right down every bolt. It takes the idea of measure twice, cut once to a whole other level. Here’s what my model looks like…

“This is the solid model. If I was to turn it into a wire frame model, you’ve got every piece.” -Sandra Maclean

“So you’ve got sleeves, because this is an insulated panel, you now have sleeves to get wiring to the exterior for exterior lighting outlets … how are we going to get wiring to your office and your studio from the electrical panels inside the building envelope?” -Sandra Maclean

“We think that far ahead, so you don’t have to drill your own and make a mess.” -Sandra Maclean

“We actually take the 3D model before it gets to this elaborate stage, and cut sections at the critical areas … we do a longitude and a latitude section cut to see what that looks like. We’ll add them to the plans. We’ll call out critical code requirements, a certain amount of insulation in your attic. Any floor changes that have to happen between, say, the garage and the main house.” -Sandra Maclean

Every aspect of the house is checked, rechecked, and checked again. I’ve talked about digital twins in other videos, but it’s pretty cool to see this applied to building a house. Once everything is approved this virtual model is what’s used for the factory build. Jay Lepple, who runs production at the Keene facility, walked me around the floor to see my house getting built.

“Over here, we can see your project, actually. What we do is we break up the panels into these simple, 3D geometric shapes, and we break up the whole building. We’ve got our exterior walls, our interior walls, all of our truss and sheathing, and all of our open exterior things, which are uninsulated. That could be ceilings, exterior roofs.” -Jay Lepple

“The reason we do this is so that we know, first of all, it’s our batch size. This is what we produce. We can produce this, while we’re producing this, and while we’re producing this, so we know what our CNC machines are cutting. Also, it informs us … it’s always color-coordinated as we are going to raise the building on-site, so it says, “Here’s our first bundle, our first panels. This is where we’re going to start.” It also informs us on our trucking and how many trucks we need to get all the product to the site.” -Jay Lepple

“Moving over here, we have all of our bulk inventory for the process, production app and on-site. You’ll see all the bulk inventory, and once a day, a person goes around and grabs the supplies. We have about 20 satellite carts, we call them, out on the shop floor. This allows us to just have just in time delivery and not overstock too much material or products, whether it be tapes, fasteners, anything that’s going to the site or the different stations here.” -Jay Lepple

“As we move through here, you’re going to see some large, engineered lumber. A lot of this is used on your house, but this is a little different than going to the downtown lumberyard where we have 16-foot material being grabbed in your pickup truck. This is all 36-foot long stock that’s procured from Canada … the reason we use engineered material is because of our CNC equipment, it becomes way more accurate to control the length of everything and to cut it, to drill it for all the CNC processes.” -Jay Lepple

This was the first area that drove home the scale of production they’re working with. Since they know the exact amount of cut material needed for my project, there’s very little waste. You’re not having to buy extra wood just for my project that may be tossed at the end of the project. This wood spans multiple projects, which helps to reduce waste. It also means that they can buy at scale and save on costs. This also ties right back to the virtual fabrication model I showed earlier. Jay showed me how that translates to the factory floor.

“What happens with those simple, geometric shapes is there’s an element routine or an algorithm that’s run on this, and it automatically knows where the door ROs are going to be, the jacks, the king studs, our headers, depending on what type of wall component it is.” -Jay Lepple

“Right.” -Matt Ferrell

“If I were to click here, this just gives me all the attributes. It tells me it’s a nine and a half inch I-joist. It’s got the production number, which they need for the shop drawings on the floor … it gives us all these different attributes that are either color coded for the machine, or the job, or the numbers. Then that results in a direct export to this machine behind me here.” -Jay Lepple

“It has a giant saw blade that’s able to cut it down. Then in the front there, there’s a revolver mill, and end mill, and that’s doing all the different functions, whether it be drilling or shaping.” -Jay Lepple

The benefit of using a CNC machine to produce the parts like this is that it simplifies the assembly and can reduce the number of parts you need.

“While we don’t have all the shaping techniques on that piece, we have a lot on something like this, our SC1 operator did for me, and you can see at the top. That’s a tenon that’s done with a revolver mill. This is also just taking out huge forms of wood. Instead of putting in blocking in-between studs now, they can actually take material out of the studs and put a whole linear piece of blocking in, which just makes it really easy, and it obviously puts right where it goes on it. You don’t have to think about that.” -Jay Lepple

“Then I always have this to show people. Just if you could imagine this being a ledger up on the wall mounted to the wall, and this being roof rafters for a screened porch or something like this, this takes out a lot of the guess work. Nobody’s running the tape measure. This is an engineered joint. They don’t have to pull out the tape, mark the joint. It’s already there.” -Jay Lepple

“This goes into that piece, so it’s like a puzzle, and you just put three stick nails in it and it’s done. I don’t have to then have procurement order joist hangers. They don’t have to find the joist hangers, bring them to the correct spot, nail them all off, so there’s a lot of intelligence built in, and our engineering is very involved with all that to get us some standard specs that we can always use.” -Jay Lepple

This is when Jay walked me further down the line to see some of my wall panels getting produced. Along the way he took a second to walk me through what sets Unity’s wall design apart.

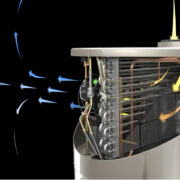

“When we get to passive house levels with totally thermal bridge free assemblies, I can show you a little something right here that can explain a little bit of the process upfront. If we could just take a look at this section, we’ve got a framing layer, which we use an I-joist on your wall. We’ve got our interior seven-sixteenths OSB, which is our vapor control layer, and then we have a 2×3 stud that allows us to run all of our mechanicals in terms of wiring and things like that. You’ll see that a little better.” -Jay Lepple

There’s a bit to unpack there, but in short they use 9 inch I-beams as studs. This reduces the amount of material needed, but the I-beam also reduces the thermal bridging. Zip sheathing, which acts as a vapor barrier, is used on both sides of the I-beam with densely packed cellulose insulation in between (we’ll see that process in a bit). And then on the inside of the wall panel they place 2×3 studs to give space for running electrical and plumbing and attaching drywall.

“What Matt’s going to do is he’s just going to start extruding this wall panel, and putting the studs on there.” -Jay Lepple

All of the material you see Matt using on this process is right there with rollers to make it easy to pull onto the line. Guides that help him make sure the alignment is right and then the machine can saw and nail away on its own.

“That’s also a direct export from our CAD software to these machines, so there’s no XY conversion or anything like that. It’s right to the machine. He just pumped up these air cylinders here to get that assembly, and he just pops them back down, pushes it in place, and it just … keeps firing off those stick nails right there.” -Jay Lepple

After this step we followed the wall panel to the next station on the line which is where they apply the Zip sheathing. Not only does this act as their vapor barrier, but it also doubles as structure.

“Not only is it for the vapor control layer, but we do this on both sides to be resilient and have a robust product being done on-site. Because if we see a small amount of weather, we don’t want any leaching into our panels with rain or anything like that.” -Jay Lepple

“You can see, again, ergonomically, he’s able to use this with a vacuum lift and pull sheaths. These guys do a lot of sheaths. Every day, we have five of these within the facility.” -Jay Lepple

“What he’s doing, he’s tacking the last piece of sheathing and, I believe, he then has one more little piece. Then this machine is a giant bridge that runs over the top of this, and it will be nailing in its own pattern. It’s a little wild how it nails, but it’s got two nailers on it, and then it has a router on it, so it nails everything off to spec.” -Jay Lepple

Okay, so Jay said the machine that runs over the top was “a little wild” … he was right … but he left out how loud it is. It was kind of like watching a gigantic, terrifying ink jet printer that shoots nails instead of ink.

“We actually have tandem ones going now behind us as well. It looks as if it’s starting with the bottom and top plate, and then it’s going around on these various different things. I don’t know why, but it’s going through all the code of how it wants to nail, and that’s just automatically exported in that way.” -Jay Lepple

“It’s figuring out the best way to do it?” -Matt Ferrell

“Yeah. After this is all done, the router will go around, and these guys, they’re getting so good at this now that that routing is exact, which means that framing underneath really needs to be exact as well, or else it’s not going to look the same.” -Jay Lepple

After that craziness the machine moved on to routing out the windows, sconce boxes, and other cutouts.

“If we move down here, we can see after this gets taped, we actually, right behind it, grab the open built layer. That’ll be dragged up top here and nailed off. That’s actually what Evan has done here already. This has been dragged up. It’s all been taped off. Even the penetrations have been taped off just to make sure, again, that those blower door test numbers are going to work out.” -Jay Lepple

“We know it’s going to be foamed later, so we’re not worried about it. We just got to make sure that when we run the blower door test. You can see, these are 2x3s that are put in with a five-inch nail on the studs. You can see with the SC3, we’re hogging out channels for the Romex, and so the electrician team just come in and fish wire, rather than drilling every single stud through there.” -Jay Lepple

Jumping in again here. As I’ve mentioned before about the Passive House standard, one of the key elements is to reduce thermal bridging through the thermal envelope of the house. A stud in your wall can act as a thermal bridge because it will transfer the heat through the wood bypassing any insulation you have in between those studs. The level of thought and engineering that’s gone into the Unity design to help account for thermal bridging was really driven home to me at this part of the tour when Jay explained how the walls are attached to the foundation.

“I don’t know if we can see it on this wall. Yeah, there’s little holes on the bottom of here. We actually, when this is done, we put a PT piece of plywood that stitched this framing member and this framing member together.” -Jay Lepple

“Together, okay.” -Matt Ferrell

“Then when we’re at your jobsite with the foundation and we’re snapping lines, these panels will fly in with the crane. After layout, we can just go right to town with drilling this into the concrete through these holes at every two-foot on center, and drilling and tightening into the concrete, so we actually don’t have J-bolts sticking out of the foundation where they’re somewhere inside the envelope. They’re actually all the way inside the envelope, so not dealing with any thermal conductivity in and out.” -Jay Lepple

The level of thought that’s gone into the placement of a bolt to help reduce thermal bridging. Kind of incredible. Anyway, at this point the wall is flipped from the interior side to the exterior side so they can inject the insulation into the wall panel.

“This is an ISOCELL machine that has six different ports in it … we have preset recipes within this tablet right here, either on the platen or right on that iPad right there, and it allows us to deal with different depths, different size cavities in length and width.” -Jay Lepple

“When I say preset recipes, that’s for getting the correct density. He has a chart above the tablet there that tells us what the density requirements are for each square foot, or sorry, cubic foot. We actually take core samples, that’s part of our checklist, and weigh them with that tube that he’s got right there. He weighs them to make sure he’s within the density requirements for that size cavity.” -Jay Lepple

“Right.” -Matt Ferrell

“We try to get, typical density is 3.5 per cubic foot. We try to get a little higher than that. We’re putting these vertically. They’re being driven over the road, kind of an agitator, and so we try to make sure we go a little bit more dense so there’s no settling that occurs.” -Jay Lepple

If you’re curious what the insulation value, or R value, is when the wall is complete, it will be R-35. So after the insulation it has more sheathing applied and nailed down, then taped to get an airtight and waterproof seal. After that’s all complete the wall is stood upright and slid onto a track where the triple paned, European style doors and windows are installed.

“These are tilt, turn mid-mount windows, and what we’re able to do with these, these are some of your fixed windows, but we’ll see some operable ones in a minute. We’re able to take these fixed units, you can see this suction cup machine right here, this lifter, this is a heavy lift window. This is triple glazed, two guys minimum, or they might get hurt, so we have this nice vacuum lifter. We actually can pick this up and pre-tape all of the frame here.” -Jay Lepple

“Then what it would look like then is this. We would foam all of this. We’ve got an easy-opening window. You want to try out your window?” -Jay Lepple“I do want to try out my window. I’ve got to try this out. This is pretty cool.” -Matt Ferrell

“We actually have a door installed over here.” -Jay Lepple

“Oh, this is a living room wall.” -Matt Ferrell

“See, you know it.” -Jay Lepple

“I know exactly where this is.” -Matt Ferrell

“Yup. Again, we’ve got a tilt, turn window but now we have a swing door here that’s ready to go. This is a little different. This is hard in the panelized world, so we actually create what we call a door buck. There’s actually going to be a knockout in your foundation.” -Jay Lepple

Am I weird for being super excited for those European style, triple glazed, tilt/turn windows? After all of the panels were completed, they were packaged up, wrapped, and set aside for final delivery. As you can see from their process, they’re applying building science to build more sustainable, energy efficient homes, in a more cost efficient way. In a general sense, when you can improve mass manufacturing of pretty much anything, you can drive down the costs to make it. It’s no different when it comes to building a home like this or the latest smartphone. If you were building a home from scratch on site to the same specifications, it would be more expensive to produce than using the methods Unity is doing inside a climate controlled facility. You don’t have to worry about weather impacting production, the materials you’re using, or excess waste. However, as I mentioned near the beginning, one of the things that sets this whole process apart is the virtual fabrication. When I asked Tedd Benson what was next for Unity, he mentioned this…

“We’re developing a software platform to make this automation that you’re seeing in the actual production of panels and so on. We want to bring that into the software world so that when you produce a plan, it is ready for production. So that’s been a big project of ours for quite a few years. And for the last three years, we’ve actually had a development team on the project. And we’re going to bring a new company to market in the next year.” -Tedd Benson

“Is that software going to be available to other companies to take advantage of?” -Matt Ferrell

“Yes. Yep. Yeah.” -Tedd Benson

“That’s fantastic.” -Matt Ferrell

“It’ll be open source, and we’ll certainly be connected to the development of it, but one important aspect of it is that it will certainly be neutral and available to other companies like ours, even the competitors and to others in the marketplace, architects, and builders, and developers, and supplier manufacturers as well.” -Tedd Benson

Tedd has been trying to push the building industry forward for decades now to build resilient, long lasting, sustainable homes. The fact they’ll be open sourcing this software for anyone to use, shows that commitment. After seeing this in person, my main thought was, “why aren’t we doing this everywhere?” There’s still a lot more to come for my net zero home build, including everything from drilling for my geothermal well, the on-site assembly and finishing of everything from the factory, solar and battery storage, etc. Stay tuned because there’s a lot more to come.

Comments