- Figure 1 from http://www.cell.com/joule/pdf/S2542-4351(18)30583-X.pdf

- IEA – Data and statistics, Renewable electricity generation by source (non-combustible), World 1990-2018 ↩︎

- Advantages and disadvantages of renewable energy ↩︎

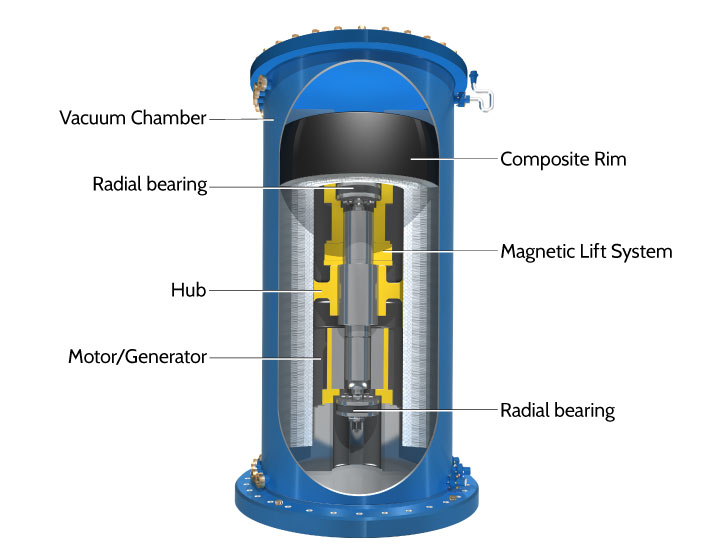

- Flywheels. SANDIA REPORT. SAND2015-3976 ↩︎

- Flywheels ↩︎

- Howell Torpedo No.24 ↩︎

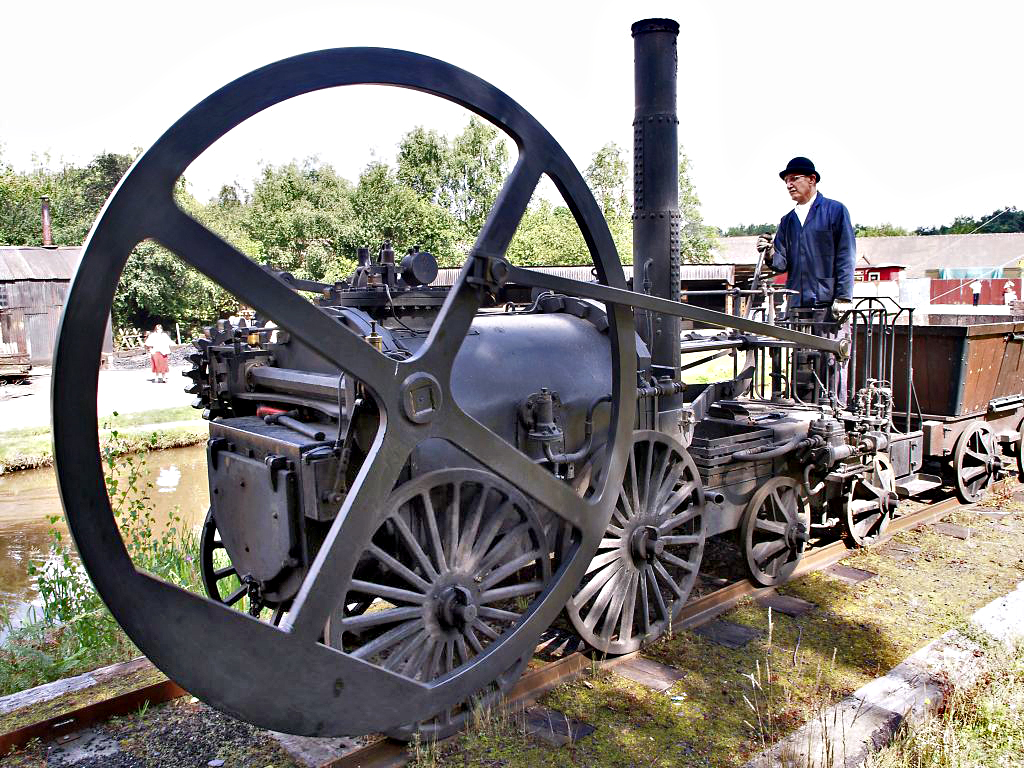

- History of flywheel energy storage systems ↩︎

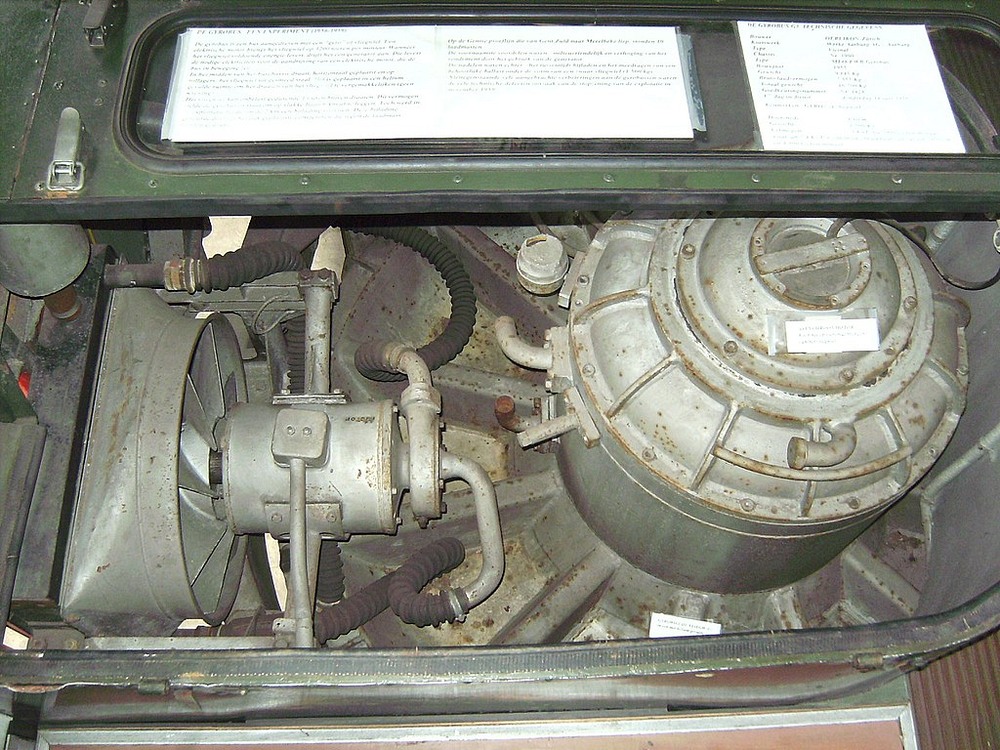

- Gyrobus: The Flywheel-Powered Public Transportation ↩︎

- 3.5.1.3 Flywheels. Hybrid Energy Systems. Encyclopedia of Energy, 2004, Pages 215-229 ↩︎

- Advantages of Magnetic Bearings ↩︎

- Flywheels. Energy|Energy Storage. Encyclopedia of Electrochemical Power Sources, 2009, Pages 215-231 ↩︎

- Flywheel Energy Storage Systems (FESS) ↩︎

- 4.2.4 – Flywheel. Smart Grid Energy Storage. The Power Grid, 2017, Pages 93-135) ↩︎

- Mechanical Energy Storage) ↩︎

- 1.11.6.3 – Flywheels. Storage Options for Photovoltaics. Comprehensive Renewable Energy, Volume 1, 2012, Pages 199-212 ↩︎

- Energy Storage Electricity storage technologies – IVA’s Electricity Crossroads project ↩︎

- Control Moment Gyroscope ↩︎

- Beacon Power Operating Plants – Stephentown, New York ↩︎

- Amber Kinetics M32 ↩︎

- Utility of the Future—Capturing Multiple Revenue Streams from Storage Investments ↩︎

- Only Ruggedized Energy Storage Solution ↩︎

- Storing Renewable Energy in Flywheels ↩︎

- Electricity Storage and Renewables: Costs and Markets to 2030 ↩︎

- Projecting the Future Levelized Cost of Electricity Storage Technologies ↩︎

- Hybrid Lithium Battery and Flywheel Energy Storage System Joins Dutch Grid51(18)30583-X.pdf) ↩︎

Comments