With the growing popularity of solar and wind, we sometimes forget another powerful low-carbon energy source: nuclear. It can be a divisive topic, but there’s a really interesting alternative to building out massive, expensive nuclear plants that’s worth talking about: Small Modular Reactors. What are they? What are the benefits? And do they really address the downsides of nuclear energy?

When the word nuclear comes up, most people think of mushroom clouds, wars, and disasters. But, even though there is a scary history behind nuclear energy, many consider it essential for establishing a reliable carbon-free energy supply. We’ve been producing nuclear energy since the first nuclear power plant was connected to the Soviet power grid in 1954 1. It’s widely considered to be a stable, carbon-friendly energy source that can be used to support the intermittency of renewables such as wind and solar.

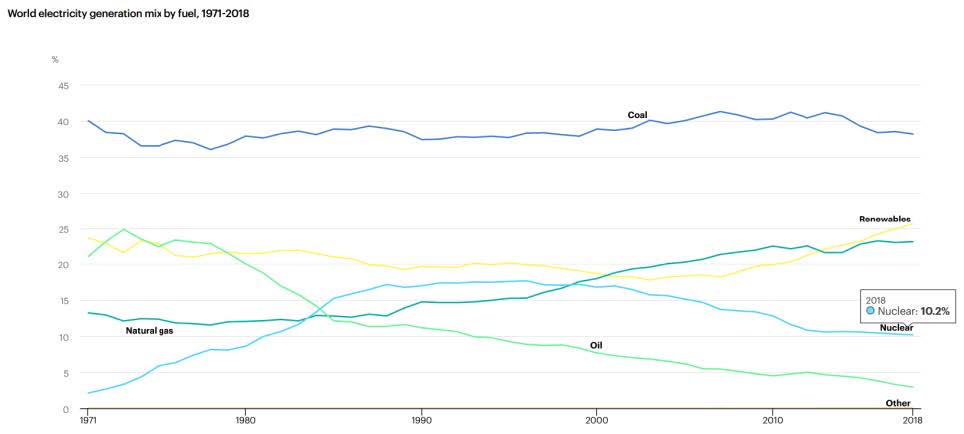

Some countries, like France (71.7%), Slovakia (55%), Ukraine (53%), and Hungary (50.6%) rely on nuclear to produce electricity. And it accounted for 10.3% of the world’s electricity generation in 2019 2, 3. However, that number was higher in the past. In 1996, nuclear accounted for 17.7% of the global power generation 4. Only a net of 2.4 GW of new nuclear generation capacity came online in 2019, compared to 98 GW of solar PV and 59.2 GW of wind. What’s caused that sizable decrease? And why aren’t we building out more nuclear?

The major events of Three Mile Island, Chernobyl, and the more recently Fukushima certainly made people fear nuclear energy and stalled the industry’s growth. But, the safety threat and nuclear waste aren’t the only causes of nuclear energy being left out in the cold by governments and investors.

The intermittency of renewables needs to be supported by fast and responsive energy production. Nuclear power plants could be a stable and low-carbon solution for this problem, but they’re complex, expensive, and usually take about 6 years to build … and some have some significant delays during construction 5. The time it takes varies project to project, but one report gave a cost estimate for a new US nuclear power plant of $5,945/kW 6. On the other hand, the average cost of natural gas generators installed in 2018 was $837/kW, and the construction of those come in around two years 5, 7. So you can see why natural gas power plants are more appealing to a utility, even though they’re not as carbon-friendly as nuclear.

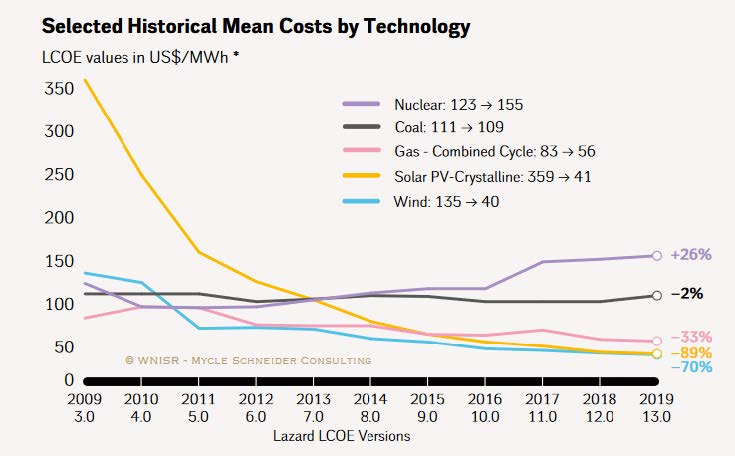

According to the World Nuclear Industry Status Report 2020, the Levelized Cost of Energy (LCOE) from nuclear power rose from around $117/MWh in 2015 to $155 by 2019. In comparison the LCOE of solar and wind reached $40/MWh and $41/MWh, respectively. The report stated: “What is remarkable about these trends, is that the costs of renewables continue to fall due to incremental manufacturing and installation improvements while nuclear, despite over half a century of industrial experience, continues to see costs rising,” 3. The nuclear industry needs an escape route … something to make it more financially attractive, reduce construction time, but still comply with all the numerous safety standards that are needed. That escape route has been to invest in new reactor technology.

I have another video about Thorium Reactors on my channel, showing its advantages and challenges, but the other trend I’ve seen in my research, and the comments from a lot of you, has been around Small Modular Reactors (SMRs). It promises to reduce construction cost and time, as well as improve safety. Many people believe they can be the future of nuclear power, but what is it exactly?

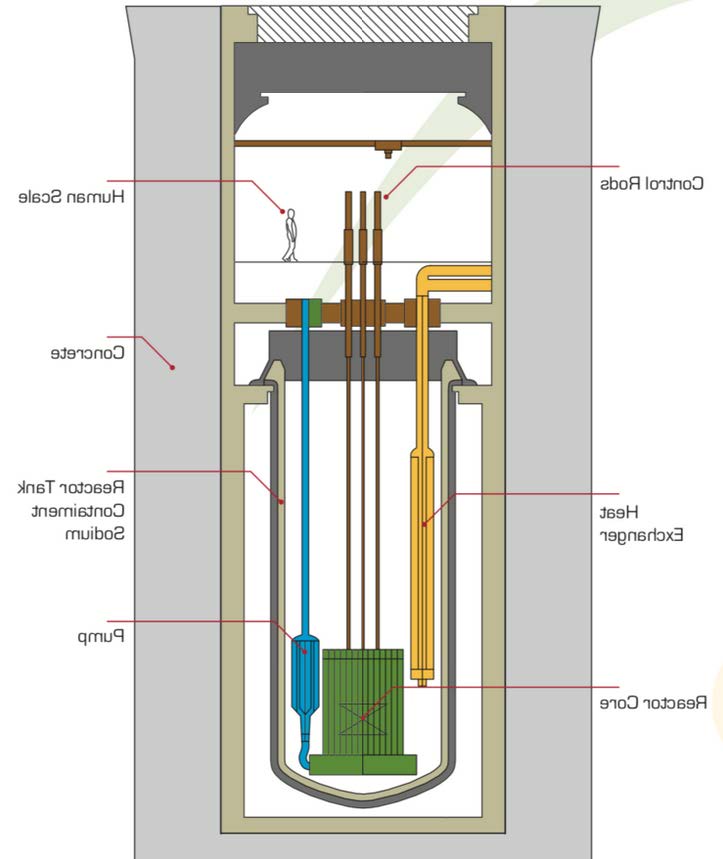

Compared to “regular” sized reactors that are really big, Small Modular Reactors have a much smaller footprint, which means that they can be built more quickly and safely in factories, and then shipped to the installation site. But how small is “small? Well, they’re small enough to fit in trucks and shipping containers. Compared to conventional large-scale nuclear reactors that have to be built on-site and have unique designs, SMRs can be manufactured in factories with standardized designs. This means you can scale production, reduce costs, and lower the risk of delays in the construction of nuclear power plants 8, 9, 10.

The World Nuclear Association defines SMRs as nuclear reactors generally 300 MW equivalent or less, designed with modularity in mind. To round off the SMR terminology, there are also units called “very small modular reactors,” or VSMRs, of up to 15 MW 9. Compared to the world’s largest reactor that have topped 1.6 GW of power capacity, this new technology is pretty small, isn’t it 11? NuScale Power, one of the front-runners in SMR development has designed a small modular reactor (SMR) that would take up 1% of the space of a conventional reactor. Whereas a typical commercial reactor cranks out a gigawatt of power, each NuScale SMR would generate just 60 MW 12 .

The in-factory fabrication feature of SMRs can significantly reduce on-site preparation and construction cost, as well as make it possible to set them in remote locations that wouldn’t normally be possible with a larger power plant. Also, SMRs can be linked with other energy sources, including renewables and fossil fuels, to increase grid stability and security 10.

Talking about money, for about $3 billion, NuScale would install multiple 12 MW SMRs to build a 720 MW nuclear power plant. That’s about 20% cheaper per-megawatt than the $14 billion quoted for two traditional 1.25GW units currently being installed near Waynesboro, Georgia. And that construction has been hit by delays and a ballooning cost up to $28 billion 8.

What about safety?

Nuclear power plants are complex buildings that rely on external power systems such as AC power, backup generators, and batteries to cool down the reactor’s fuel in the case of a power loss, which increases accident risks. Suppose something that wasn’t considered in the design happens. In that case, it may cause the system to fail, similar to what happened in the Fukushima Daiichi nuclear disaster in 2011 when a second tsunami that wasn’t expected hit the nuclear plant.

On top of that, maintenance and refueling are an additional complexity for nuclear power plants. Every 18 to 24 months, these power plants are shut down for refueling, which usually takes a month without energy production, and SMRs can be a promising candidate to reduce these downsides 13, 14.

When we talk about nuclear reactors, we refer to a containment building with large walls, safety measures, and cooling. But, with SMRs, it’s different. These small-sized reactors fit right into other structures or come with their own containment structure. And some of these designs have a long refueling cycle. For example, the 5 MW Micro Modular Reactor, from Ultra Safe Nuclear Corporation (USNC) … you gotta love that name … requires no refueling in its 20-year operating lifetime, and the 100 MW ARC-100 small modular reactor would have a refueling cycle of a similar 20 years.

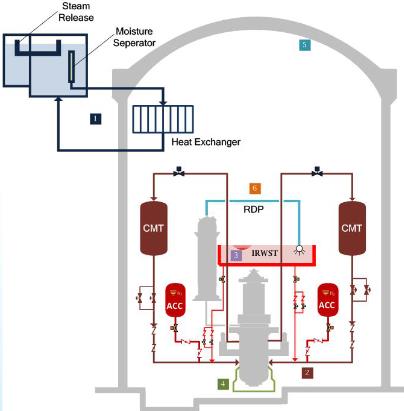

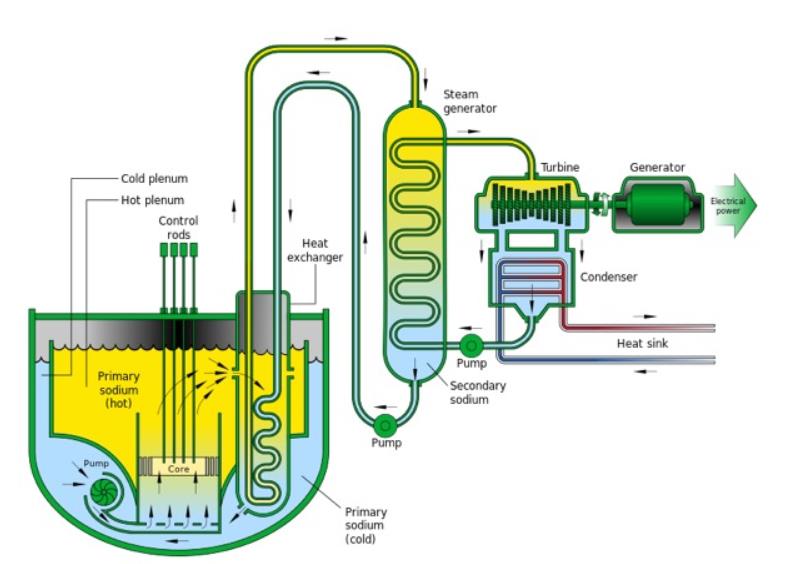

SMRs enhance safety and security through lower thermal power of the reactor core and use of passive safety systems. That means they have less reliance on active safety systems like additional pumps and AC grid power, generators, and batteries. NuScale’s SMR employs natural water circulation to passively cool its reactor down. The thermal safety system incorporates an on-site water reservoir located on the sides of the outer vessel, which removes the heat from the core, avoiding a complete meltdown. In an eventual emergency, specialized valves open automatically, which allows steam to be released from the reactor vessel into the containment vessel. The steam then condenses, and water flows back down into the core through the second set of valves at the bottom of the reactor vessel. This helps cool the reactor down. The steam generated by boiling water recirculates, setting up a passive safety cooling process that lasts until the heat and pressure finally stabilizes. All this cooling and power control happens with no external interference, no AC or DC power, no operator, and no additional water, similar to proposed molten-salt thorium reactors 15, 16, 17.

Considering all these advantages, many countries have been investing a lot of money in research and development of SMRs. The Oregon-based NuScale, for example, has spent more than $800 million on its SMR design 12. In 2010, the company estimated a capital cost for a 12-module, 540 MW NuScale plant would be about $4,000/kW, which rose to $5,078/kW net in 2014 and an LCOE presumed to be about $100/MWh for the first unit. In June 2018, the company declared that its reactor could produce 20% more power than originally planned. Subject to Nuclear Regulatory Commission approval, this would lower the overall capital cost to about $4,200/kW and lower the LCOE by 18% 9. Other American SMR developers include GE Hitachi Nuclear Energy, Bill Gates-backed TerraPower, X-Energy, and Hyperion Power Generation.

China National Nuclear Corporation (CNNC) announced in 2019 it would start building a demonstration of its 125 MW ACP100 small modular reactor on the north-west side of the existing Changjiang Nuclear Power Plant by the end of the year.

Canadian ARC Nuclear is also developing an exportable, factory-produced, 100 MW sodium coolant nuclear reactor with fuel costs fixed for more than 20 years. They also have a company called Terrestrial Energy that’s been developing and integrating components from two existing designs; the Denatured Molten Salt Reactor (DMSR) and Small Modular Advanced High Temperature Reactor (smAHRT) … yeah, smart 20.

Russia is also dabbling in this area. The nuclear engineering company OKBM Afrikantov launched the first floating nuclear power plant. Akademik Lomonosov, is a power barge that employs 2 35MW SMRs. It started operation in December 2019 in its permanent location in the Chukotka district, and by May 2020 was fully commissioned and had delivered 47.3GWh of energy, covering 20% of demand in the region 22, 23.

But, is this all to good to be true?

So are SMRs too good to be true? Although progress has been made in SMR technology, licensing and certification are a major stumbling block for SMRs, as well as potential design changes and increased security. NuScale design, for example, is still in the licensing stage and faces important security questions, which include potential problems with the system that automatically shuts down its reactors in eventual emergencies 24. Normally, convection circulates water laced with boron to control the nuclear reaction through the core of NuScale’s reactor. As I mentioned earlier, if the reactor overheats, it shuts down and valves release steam into the containment vessel, where it condenses and flows back into the core. However, the condensed water can be low in boron, and reviewers are concerned that low boron level might mean it wouldn’t be able to stop the core. This has complicated their approval process 25.

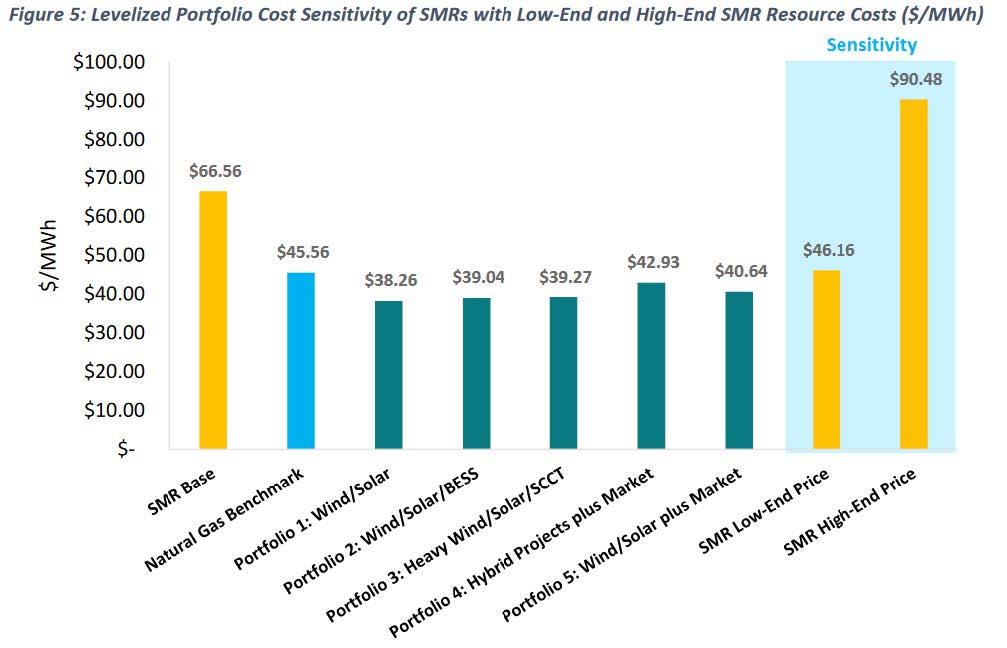

In addition to that, even though SMRs can be cheaper and safer, they still have to contend with economies of scale. Conventional power plants have thousands of Megawatts of power production capacity compared to dozens or hundreds of Megawatts for SMRs. An analysis performed by Energy Strategies for the Healthy Environment Alliance of Utah in 2019 showed an SMR LCOE range of $46.66/MWh to $90.48/MWh, and that’s with a lot of uncertainty around resource costs. Nuclear power’s biggest rival, natural gas, had an LCOE of $45.56/MWh 26.

Another issue that’s pointed out by critics of nuclear power is the unresolved problem of what to do with long-lived radioactive waste. SMRs that use a pressurized water reactor will still generate highly radioactive fuel, and no country has proposed a permanent solution for how to safely store this type of waste 27, 28. Dr. Gordon Edwards, The president of the Canadian Coalition for Nuclear Responsibility (CCNR) wrote:

“Radioactive left-over used fuel from the new (SMR) reactors will still require safe storage for hundreds of thousands of years.” -Gordon Edwards, president of the Canadian Coalition for Nuclear Responsibility (CCNR) 29

The International Atomic Energy Agency has also written about this topic.

“Solutions for managing spent fuel and radioactive waste arising from SMRs will be one of the most important factors to take into account when choosing a technology, along with the security of fuel supply.” -Christophe Xerri, IAEA Director of Nuclear Fuel Cycle and Waste Technology 30

Despite the challenges, SMR supporters look at it as a potential solution for nuclear power to be more cost-effective, safe, and competitive against other fast response power sources to balance an increasingly intermittent power supply that comes from wind and solar power. They may be right; but there are still concerns about SMR technology that need to be addressed, and unresolved problems with nuclear power in general that need solutions before this carbon-free power source can be considered a viable, worldwide option.

Jump into the comments and let me know what you think. And if there’s anything I missed with SMRs. If you liked this video be sure to check out one of the ones I have linked right here. Be sure to subscribe and hit the notification bell if you think I’ve earned it. And as always, thanks so much for watching, I’ll see you in the next one.

- “Outline History of Nuclear Energy,” February 2020 ↩︎

“Economics of Nuclear Reactor,” Illinois EnergyProf, May 2019. ↩︎

“Economics of Nuclear Power,” World Nuclear Association, March 2020. ↩︎

“Construction cost data for electric generators installed in 2018,” EIA, 10 August 2020. ↩︎

“So, what exactly are small modular nuclear reactors?,” 09 September 2020. ↩︎

“Benefits of Small Modular Reactors (SMRs),” Office of Nuclear Energy ↩︎

“Smaller, safer, cheaper: One company aims to reinvent the nuclear reactor and save a warming planet,” 21 February 2019. ↩︎

“A Milestone for Small Modular Reactors (SMR 2020),” 22 September 2020. ↩︎

“See how a nuclear power plant refuels,” Duke Energy, 03 January 2019. ↩︎

“What Should I Do if a Small Modular Reactor Loses Off-Site Power?,” Office of Nuclear Energy, 2 September 2020. ↩︎

“Advantages and Disadvantages of Small Modular Reactors.” ↩︎

“Advanced Small Modular Reactors (SMRs),” Office of Nuclear Energy. ↩︎

“Small Modular Reactors: interview with NuScale’s Jose Reyes,” 2019. ↩︎

“CNNC’s ACP100 SMR: Technique Features and Progress in China,” Nuclear Power Institute of China, 21 October 2016. ↩︎

“List of small modular reactor designs,” Wikipedia, 29 October 2020. ↩︎

“Akademik Lomonosov Floating Nuclear Power Plant,” NS Energy. ↩︎

“NuScale Faces Questions on Nuclear Reactor Safety and Financing Its First Project,” Greentech Media, 27 October 2020. ↩︎

“Smaller, cheaper reactor aims to revive nuclear industry, but design problems raise safety concerns,” Sciencemag, 18 August 2020. ↩︎

“Analyzing the Cost of Small Modular Reactors and Alternative Power Portfolios,” Energy Strategies, May 2019. ↩︎

“Small Modular Reactors Raise Nuclear Waste Risk, Distract from Real Climate Solutions,” Energy Central, 14 July 2020. ↩︎

“The countries building miniature nuclear reactors,” BBC, 09 March 2020. ↩︎

“Radioactive waste: a big problem for New Brunswick’s proposed new nuclear reactors,” NB Media Co-Op, 29 June 2020. ↩︎

“Small Modular Reactors: A Challenge for Spent Fuel Management?,” IAEA, 8 August 2019 ↩︎

Comments