Plastic changed the course of manufacturing forever, but a lot of that came at a cost that’s plaguing us now. About 91% of plastic isn’t recycled and we consume about 5 grams of micro plastic waste in our food every week.1 2 But there’s a possible solution: fungus. Yes, fungus. Mycelium technology might be the next big boom … like this mycelium brick … a plastic-like replacement with many uses and new opportunities for products … maybe even wearable technology. Let’s explore mycelium technology and how it can help us achieve a more renewable and cleaner future … and one where we don’t end up eating so much plastic.

When we think about plastics, different types, shapes, colors and sizes, like soda bottles, spring to mind. But, from a chemist’s perspective, they’re all are made of the same class of materials: polymers. While Bakelite, which was the first synthetic plastic created from organic compounds, was created in 1907, polymers weren’t discovered until 1920 by Hermann Staudinger.3 A polymer is a broad term that encompasses a substance with large molecules made up of repeating subunits that are bonded together.

Just as it was for several other materials, World War II was a great impetus for the development of plastic and chemical innovations, like Polyethylene, Polystyrene, and Nylon. It’s kind of a dark side of innovation, but war can help accelerate things. Later in the 1950s, plastics manufacturers started to make consumer products as an outlet for the materials they developed in the war. To quote the movie “The Graduate,” “Just one word … Plastics.” During that decade, manufacturers introduced polyester and polypropylene, one of the most used polymers in the world. 3

Plastics have made our life a lot easier to store liquid and food, it costs much less than other materials, it’s water and heat resistant, and durable. Sadly, the plastic industry oversold it’s recyclability … it’s cheaper to make new than to recycle old. Combine that with its excessive use and non-biodegradable nature and plastics have become one of the most wide-spread, harmful substances around the world. 4

In America, 100 billion plastic bags are thrown away every year, not to mention all other packaging materials made of plastics that are discarded. The problem is that they can hang around in the environment for hundreds of years, and burning plastics releases toxic chemicals that can harm plants and animals. But it turns out that we may have a robust, sustainable alternative to replace plastic: Mycelium. 4 5

This organism is the underground, root-like body for fungi that produce mushrooms. So if you compare it to a plant, mycelium is the root and the mushroom is the flower. The mushrooms that we eat are only a small, visible part of a much larger organism.

Fungi are important in ecosystems due to their ability to recycle nutrients, allowing previously locked away nutrients to become available to other organisms, like plants. 6 7

And they’re surprisingly robust and able to spread easily under the right conditions. All it takes is a few spores to germinate. As it grows it releases enzymes to digest the surroundings and absorb the nutrients. Eventually the cells begin to branch out and continue to grow to build a vast mycelial network, and it’s only when it’s fully built that mushrooms begin to grow. And this is where we can tap into its potential. 6 7 8

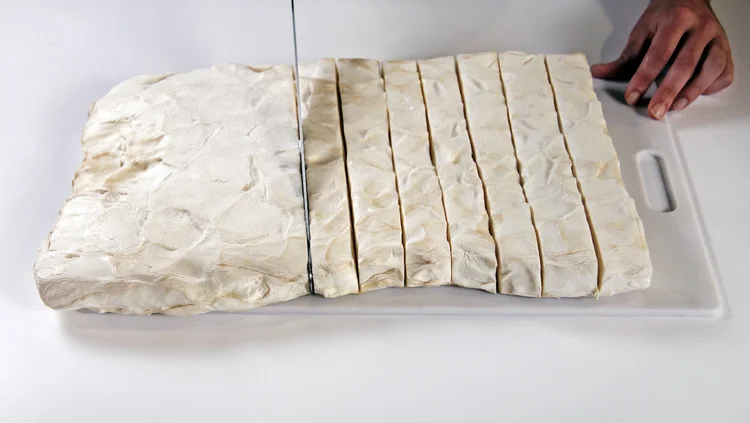

Rather than letting a mushroom pop up, humans can create forms around the mycelium as they grow to build predictable structures by providing a framework. This is an example of mycelium grown into a brick form. It’s not that different from using molds with inorganic materials like metal or plastic. We’re just letting Mother Nature do the work. The production process is kind of simple. It uses a mix of agricultural waste, which could be anything from hemp to wood chips, and it’s bound with mycelium structures.

After that, we have the base material for most mycelium-based products, known as the foam. This mixture is put in molds for whatever you’re trying to make, and placed in an environment with controlled CO2, humidity levels, airflow, and temperature. It’s a pretty quick process. Fibers can be found after just a few hours and a visible layer after a day or two. Usually within a week the mycelium foam fills the mold. Overall, it takes about a week.8 9

Mycelium foam is a great insulator, resilient, safe, strong, and biodegradable, which opens up the possibilities for a wide range of products, like packaging, clothing, construction, and even food. Unlike plastics and other synthetic materials – which can take hundreds of years to decompose – mycelium-based products naturally degrade after their intended product cycle. A nice bonus, mycelium foam is inexpensive and cost-competitive with polystyrene foam. 8 9

Mycelium technology has spawned a lot of companies from several industries around the world. The pioneer was Ecovative, which introduced mycelium technology in 2006. With more than 40 patents in 31 countries, most mycelium composites and materials out there are actually made under their license. 10

Ecovative developed several branches of products. Its MycoFlex™ technology, for example, is used to produce everything from lightweight insulating lofts for gloves to high-performance foams in footwear. It’s heat resistant, insulating, breathable, and strong. 11 12

In packaging materials, they’ve created a high-performing, cost-competitive solution that provides thermal insulation, water resistance, and decomposes in the soil within 45 days. It’s a great alternative for polystyrene. Even better, mushroom-based packaging uses only 12% of the energy from plastic production and generates 90% less CO2 equivalents. Some examples of companies licensing this technology are the Magical Mushroom Company is the U.K., Paradise Packaging Co in California, Grown.bio in the Netherlands, and BioFab in New Zealand. 13 And IKEA announced that they’re going to replace styrofoam packaging with MycoComposite for all of its products.14 I wonder if they’ll give it a name?

Ecovative has also spun out Atlast Food Co. which creates whole cut plant-based meats. Unlike other plant-based meats, the products from Atlast have almost no processing. And apologies to the vegetarians out there … this might be a little gross … but part of the reason it works so well as a fake meat is because mycelium fibers grow together in a tissue that resembles the fiber-like texture of muscle tissues in animals. Interesting … if not a little gross. 15

So we’ve had packaging and food, but what about clothing? Bolt Threads is using their Mylo™ technology as a sustainable alternative to leather that we’ll be seeing in the market through their partners, which I’m sure you’re very familiar with, Adidas, Kering, Lululemon, and Stella McCartney. 16 17 By the way, Adidas has recently launched the Adidas’ Stan Smith Mylo — the first shoe of its type to be made with a mushroom-based material. It was used in the classic three stripes, heel tab overlay and signature branding that their shoes are known for. 18

One question you may be asking yourself, I know I asked it when I was learning about this stuff, is the fungus still alive and can it keep growing within the products? I don’t think I’d want a pair of growing shoes. Although… that might save parents a lot of money on if their kids shoes grew as fast as their feet. For most commercial products, mycelium is heated long before it reaches the customer in order to kill it, maintain the product’s intended form and prevent growing mushrooms and spewing spores. 19

As if the trifecta of packaging, food, and clothing wasn’t enough … let’s step up to a quadfecta.

Mycelium has also been used in the building industry. One example is the UK-based startup Biohm. It’s been producing a mycelium insulation panel that will be the world’s first accredited mycelium insulation product. The company manufactures mycelium rigid insulation in accordance with industry standard 1200 x 2400mm sizing, but custom panels can be manufactured to meet the needs of any project.

In addition to being healthier and safer, Mycelium outperforms petrochemical/plastic-based construction materials in thermal and acoustic insulation. Tests show an acoustic absorption of at least 75% at 1000Hz for mycelium panels, which is the typical frequency of road traffic noise. On top of that, during a fire, mycelium doesn’t cause harmful toxic smoke since it’s not made of synthetic, resin-based compounds. 20

But using mushrooms as a weight-bearing construction material still requires extensive research and development. It isn’t as strong and doesn’t have a long useful lifecycle when compared to most building materials. For example, concrete can withstand between 4,000 psi – 10,000 psi, while mushroom bricks can only hold up 30 psi. 21 22

But an architectural team known as The Living designed the world’s first mushroom brick tower in 2014. The bricks used to construct the building were grown in three separate molds. It consisted of 10,000 bricks and reached 40-feet into the air.

Prior to building the tower, engineers subjected the bricks to accelerated aging – a process that simulated three years of weathering over the course of three weeks. One of the coordinators at The Living said:

“After three years of accelerated aging the material performed exactly the same as it did originally,” 22

A structure made of mycelium was also built for the Dutch Design Week. The Growing Pavilion was a temporary events space built with mycelium panels supported on a timber frame. 23

But we’re not stopping at the quadfecta … does that mean we’ve reached the pentafecta? Is that a word? Pentafecta? I’m going with it. Well, the pentafecta for mycelium is possibly in wearables … not clothing … but wearable technology.

A curious use of mycelium was investigated in a recent study titled ‘Reactive fungal wearable‘. The researchers explored the use of fungi as a potential candidate for bio wearables. Processors in tech wearables like Fitbits could be replaced by incorporating mushroom mycelium.

The researchers performed experiments on the electrical response of a hemp fabric captured by oyster fungi. They attached it to computer sensors and stimulated it with attractants and repellents. The oyster mushroom mycelium was able to recognize several external stimuli like temperature, moisture, light, some chemicals in the environment, and even electrical signals in a way that imitates the same function for sensors and processors. 24

Dr. Mohammad Mahdi Dehshibi, a researcher with the UOC’s Scene Understanding and Artificial Intelligence Lab (SUNAI), and the author of the study said:

“We can reprogramme a geometry and graph-theoretical structure of the mycelium networks and then use the fungi’s electrical activity to realize computing circuits. Fungi do not only respond to stimuli and trigger signals accordingly, but also allow us to manipulate them to carry out computational tasks, in other words, to process information.” 24

With that pentafecta of applications you can start to see the potential. The more I say “pentafecta” the worse it sounds. In 2019, the global mushroom market reached a value of US$ 53.7 Billion, and it’s expected that it can reach US$ 86.6 Billion by 2025, which is a CAGR of 8.3%. 25

A combo of cost-efficiency, consumer response, and government policies to reduce the use of plastics will drive the mycelium market. In the U.S., for example, Maine’s state government has banned polystyrene food containers, and the legislation is looking like it will spread to Colorado, Vermont, New Jersey, and Oregon as well. That action may also pave the way for a national campaign against styrofoam, which is a substance virtually impossible to recycle. The ban is expected to force restaurants and grocery stores to look for new options, making room for mushroom packaging to grow. 26 Yeah … that was a bad joke.

While restaurants and grocery store owners may not be going for mushroom packaging yet because of slightly higher costs, economies of scale and government support could result in more opportunities and reduced costs. 26 There’s a lot of possibility for mycelium-based products to branch out in the near future, and become a popular packaging material. For the other uses of mycelium, like clothing, food, and construction materials, time will tell if they can make it to the mainstream.

- Reuters – A plateful of plastic ↩︎

- National Geographic – Here’s How Much Plastic Trash is Littering the Earth ↩︎

- HISTORY OF PLASTICS ↩︎

- 7 Pros and Cons of Plastic Use – Should We Really Use Plastics? ↩︎

- What is the problem with plastic? ↩︎

- Mycelium – The Future is Fungi ↩︎

- What is Mycelium: Nature’s World Wide Web Underneath Our Feet ↩︎

- The Mycelium Revolution Is upon Us ↩︎

- Mycelium: Using Mushrooms to Make Packaging Materials ↩︎

- The Groundbreaking Mycelium Growth Behind Ecovative Design ↩︎

- MycoFlex™ ↩︎

- Apparel – Ecovative ↩︎

- MycoComposite™ ↩︎

- IKEA Starts Using Compostable Mushroom-Based Packaging For Its Products ↩︎

- Atlast Food ↩︎

- MEET MYLO™ ↩︎

- Mylo Consortium™ ↩︎

- Fungi Fashion Is Booming As Adidas Launches New Mushroom Leather Shoe ↩︎

- Made of fungi, mycelium hits market as green substitute for leather, plastic ↩︎

- BIOHM – Mycelium ↩︎

- Mycelium as a construction material ↩︎

- The Future of Construction: Mushroom Buildings ↩︎

- Pavilion grown from mycelium acts as pop-up performance space at Dutch Design Week ↩︎

- ‘Shroom FitBit: Processors In Tech Wearables Could Be Replaced With Fungi Mycelium, New Study Finds ↩︎

- Global Mushroom Market (2020 to 2025) – Global Industry Trends, Share, Size, Growth, Opportunity and Forecast – ResearchAndMarkets.com ↩︎

- Mushroom Packaging Market – Global Industry Analysis, Size, Share, Growth, Trends, and Forecast 2019 – 2027 ↩︎

Comments