The increased use of lithium-ion batteries in everything from portable electronics to grid-scale energy storage has also spurred on battery research. It’s the never-ending quest for the next big thing. And for years, now solid-state batteries have been promised as that thing. Companies like Samsung, Quantum scape, and Toyota have all announced major breakthroughs in solid-state batteries, but why all the interest and when will they actually arrive?

Lithium-ion batteries have had a massive impact on the world. Unlocking the potential in portable electronics, and more recently, electric vehicles and grid-scale energy storage. However, the aspect that a lot of us worry about when using a lithium-ion battery is safety, which is one of the big advantages of solid-state batteries, combined with its high energy density, as well as reduced size and weight.

Current lithium-ion batteries use a liquid electrolyte solution, and if they aren’t properly managed, or are damaged in an accident, they can swell from temperature variations or even leak from mechanical stress. The result of that can lead to fire. On top of that, most EVs employing lithium-ion batteries have a range of 300 miles or less, a long charging time, not to mention the loss of capacity over time with each charging cycle. In some cases that’s as much as a third of capacity lost within a decade.

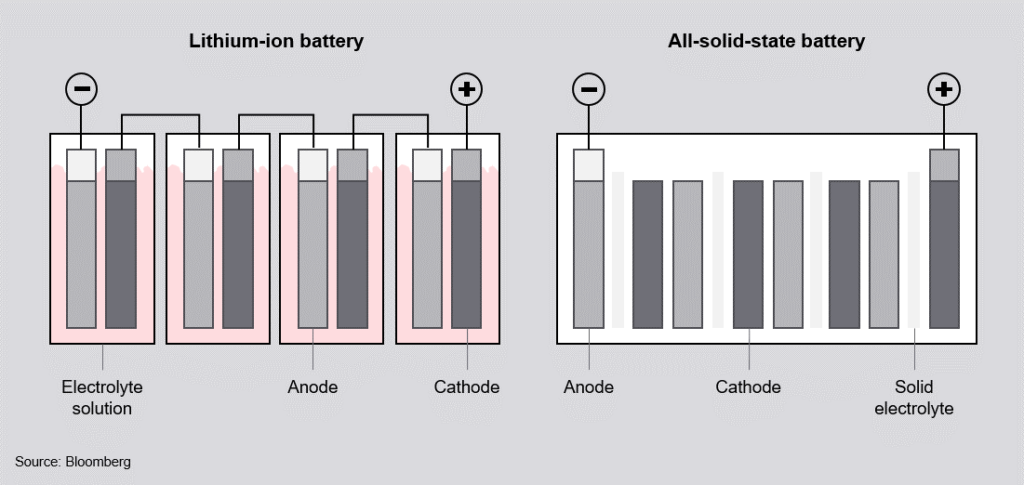

But technology doesn’t stand still. There’s always ongoing research and refinements that continue to make batteries better and more resilient. Looking for new chemical storage technologies that can increase efficiency and safety while reducing size, weight, and environmental impacts … and that’s where solid-state batteries come in. 1 2 To understand why, let’s take a moment to walk through the main difference between today’s lithium-ion batteries and a solid-state battery.

In a battery, the electrolyte is the conductive chemical mixture that allows the current to flow between the anode, which is the positively charged electrode, and the cathode, which is the negatively charged electrode. In the case of lithium-ion batteries, what separates the anode from the cathode is a liquid electrolyte solution, while in a solid-state battery … you probably guessed it … it’s a solid electrolyte.

Liquid electrolytes have some disadvantages — such as high flammability, risk of leakage, and electrolytic decomposition at high voltages, while batteries that utilize solid electrolytes have been promised to lower costs, and increase performance with incredible safety.

If you’re interested in a deeper dive, I’ve got other videos on this exact topic, 3 4 but one of the biggest benefits of solid electrolytes is the ability to use other anode materials like lithium metal.

The potential increase in energy density for a lithium-metal anode battery has been known since the mid-1970s. But, it’s also known that lithium-metal anodes have problems when used with liquid electrolytes. In this case, dendrites form when the battery is being charged. Dendrites are like stalactite formations that grow from the surface of the anode, and can lead to reduced energy density and can short-circuit the cell. The dendrites can puncture the separator between the anode and cathode … and that’s when you get exploding batteries. It’s widely believed that to make a lithium-metal anode battery, it’s necessary to employ a solid-state separator that is roughly as conductive as a liquid, resists to dendrite formation, and doesn’t react with metallic lithium. 5

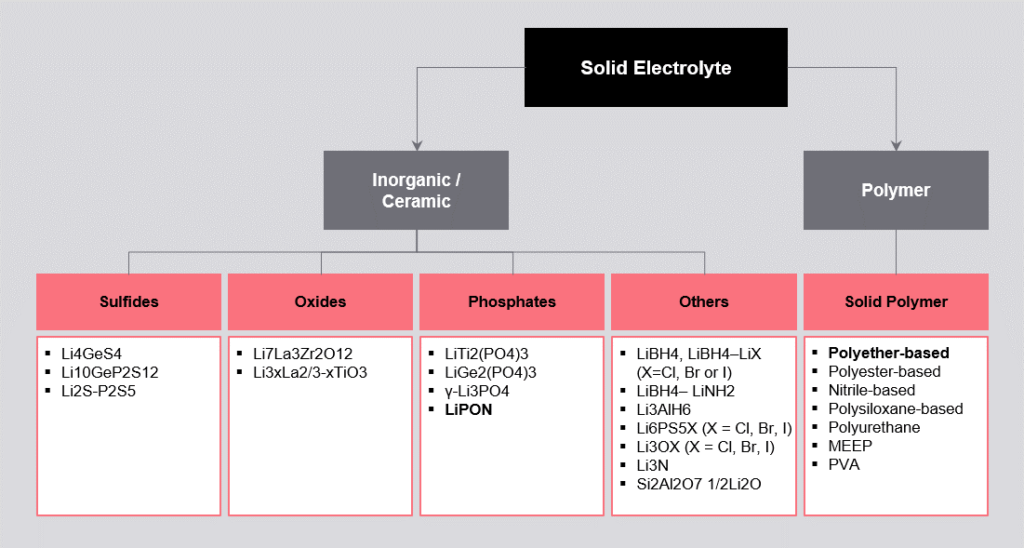

Today, there are more than 25 kinds of solid-state electrolytes, such as oxides, sulfides, phosphates, polyesters, but … I’m going to stop there so I don’t get any flashbacks to my 1970’s childhood

The promise of solid state batteries has been growing for years, like hundreds of years. It goes all the way back to Michael Faraday in the 1800s when he laid the foundation with the discovery of solid electrolytes made of silver sulfide and lead fluoride. Then, in the end of the 1950s, several electrochemical systems used solid electrolytes. Later, in 1990, Oak Ridge National Laboratory developed a brand-new version of solid-state batteries, which was later incorporated into thin film li-ion batteries. 6 7 But, since 2015, big players have been investing a lot of money into this research.

In this crazy mix of chemistries and technologies, there’s been a lot of buzz recently about new investments in the field. For example, Volkswagen got a 5% stake in QuantumScape, Dyson acquired Sakti3, Bosch acquired SEEO and Johnson Battery Technologies sold its solid-state batteries to BP. Some electric vehicle companies joined this game as well. BMW established a partnership with Solid Power, and Ionic Materials … a company in my neck of the woods here in Massachusetts … worked with Hyundai. 8

The reason for the interest from EV makers is because of how much energy you can pack in per kg, which results in either a size and weight reduction if you keep the same battery pack kWh rating, or increased driving range if you keep the battery pack weight the same. So keep an EV battery pack at 70 kWh with less weight, or increase it to something like 120 kWh with the same weight. And the benefits don’t stop there. You get batteries that operate within a wider range of temperatures, making them more robust, as well as more eco-friendly compared to conventional batteries. 9 There’s been a lot of buzz and recent announcements about solid-state batteries.

Samsung, for example, has developed a solid-state battery prototype that solves the dendrite problem by using silver-carbon (Ag-C) to form the anode, achieving a battery that’s only five micrometers thick. This ultrathin Ag-C nanocomposite layer allowed the company to boost energy density up to 900 Wh/L. For comparison, today’s best lithium-ion batteries have energy densities just below 700 Wh/L. The expansion of the company’s prototype would enable an EV to travel up to 500 miles (800 km) on a single charge, with a lifecycle of more than 1,000 charges. You’re talking about a battery pack that would last for over 500,000 miles. 10 11

From the startup perspective, California-based QuantumScape, which is actually backed by Volkswagen, released a report in December 2020 showing that its solid-state cells can charge to 80% of capacity in 15 minutes, retain more than 80% of its capacity after 800 charging cycles, and has a volumetric energy density of more than 1,000 Wh/L. In its battery, nickel manganese cobalt oxide is used as the cathode and the anode is made of pure lithium metal, like I mentioned earlier. 2 As for timing, this isn’t supposed to hit initial production until 2024.

Toyota stands at the top of the global heap with over 1,000 patents involving solid-state batteries. The EVs being developed by Toyota in partnership with Panasonic are supposed to have twice the range of a vehicle using a standard lithium-ion battery. The most impressive part, if true, is that Toyota aims to retain 90% of the battery’s performance over a 30-year lifespan, and company officials say they’d be capable of recharging from zero to full capacity in 10 minutes. Toyota is supposed to be unveiling their solid-state-based EV this year, but they’ve also stated that it won’t be in mass production until 2025. 12 13 14 15

And another company, Bolloré, is supplying batteries for use in Mercedes Benz buses. Their lithium metal polymer (LMP) operates at 80° C, so it self-stabilizes whether external temperatures are -30° C or 65° C. And it doesn’t contain cobalt, nickel, or solvents. While they’re working at very low scale right now, their next generation products are expected to start delivering to OEMs in 2026. 16 The benefits of this type of battery could give electric vehicles a wider operating range in extreme temperatures.

You’re probably seeing the trend there. 2024, 2025, and 2026. That’s when they expect these batteries to start hitting production. Why is that? Well, there are still several issues to iron out on this technology. One of which is manufacturing. Most of these batteries require very different manufacturing techniques and machinery than tradition batteries. They require extremely dry conditions during production, and the raw lithium and material capacity needed isn’t there yet. 17

One company is taking a manufacturing first approach to solid-state batteries, in order to reduce the cost of production. The American company Solid Power has been all-in on solid-state batteries and large-scale production processes for the past several years. In December 2020, they begun pilot production of a 22-layer, all-solid-state battery cell (ASSB) at its pilot line in Colorado. Their batteries are manufactured in a way that’s compatible with the industry-standard roll-to-roll manufacturing used in current lithium-ion production. 18 19 They’ve partnered with both BMW and Ford.

And if you want to look a little further out into the future, there’s glass electrolytes to consider. The lithium-ion co-inventor, and just general rock star, John B. Goodenough applied for a patent for this new technology in 2020 with Maria Helena Braga. Researchers say the new battery technology delivers three times the energy storage capacity compared to lithium-ion batteries. Tests on this technology suggest “perhaps thousands” of charge and discharge cycles, more than your typical lithium ion battery, all while withstanding a wider range of temperatures between -20° C and 60° C. 20

Carrying out this glass electrolytes concept, the University of Bayreuth, together with Tesla and Varta Microbattery, will develop novel battery separators made of glass. The project named GlasSeLIB (glass separators for lithium-ion batteries) started in March 1st 2020. 21

Considering the increasing interest in solid-state batteries, governments around the globe have been putting some money to make it happen. For example, the Japanese government has been supporting the domestic development of solid-state batteries, to remain competitive against China. Japan is organizing a fund of about 2 trillion yen ($19.2 billion) to promote decarbonization technology. Policymakers will consider using those funds to provide subsidies of hundreds of billions of yen in order to fund the development of new batteries. 12

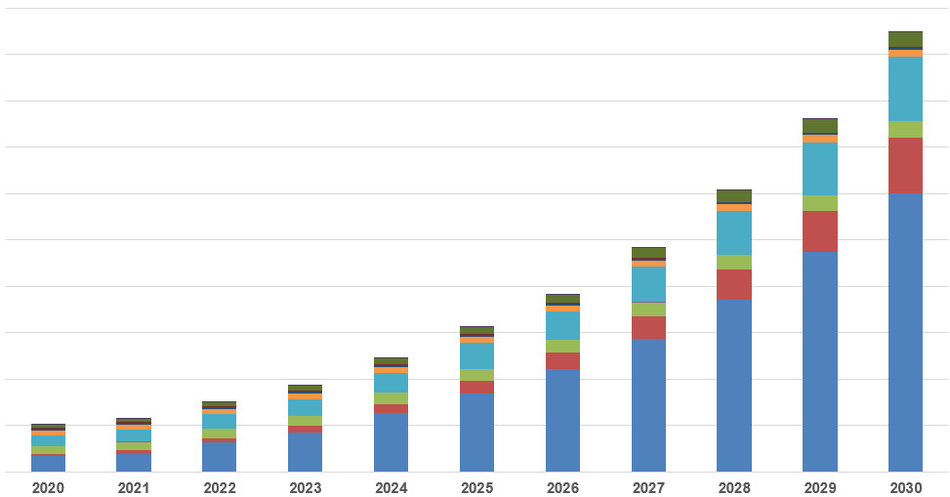

Although the COVID-19 pandemic has had a significant economic impact, the potential market size of solid-state batteries is expected to grow to over $6 billion by 2030. 8

Regardless of the underlying chemistry or manufacturing techniques, there’s a lot of moving parts to bring solid state batteries to market. All of these companies are still refining and testing their batteries. The mid-decade release timelines doesn’t mean that all of these will be producing at mass-production scale with high yields and low cost. That will take time. When we’ll be seeing mass produced solid state batteries in our EVs, portable electronics, and other devices … at an affordable price … is still uncertain. But it’s probably further out than you might think.

- What is a Solid-state Battery? ↩︎

- Solid-State Batteries Advancing Toward Promise of Fast Charging, Long Life, Safer Use ↩︎

- Overview of batteries for future automobiles ↩︎

- How to Define Anode and Cathode ↩︎

- Solid-State Battery Landscape ↩︎

- A Possible Replacement for Conventional Liquid Lithium-ion Batteries in Electric Vehicles ↩︎

- Solid-state battery ↩︎

- Revolutionary Solid-state Batteries Will Create a $6 Billion Market in 2030 ↩︎

- Solid State Batteries, 2020-2026: Advantages in Power and Density are Low-Power Draw and High-Energy Density ↩︎

- Samsung Develops 900Wh Solid-State Battery ↩︎

- Samsung Presents Groundbreaking All-Solid-State Battery Technology to ‘Nature Energy’ ↩︎

- Toyota’s game-changing solid-state battery en route for 2021 debut ↩︎

- Toyota to unveil solid-state battery EV prototype next year ↩︎

- Toyota’s Quick-Charging Solid-State Battery Coming in 2025 ↩︎

- Toyota’s Solid-State Battery Prototype Could Be an EV Game Changer ↩︎

- ↩︎

- Solid-state batteries will mean the advent of 1000-km ranges and 10-minute recharging times ↩︎

- Solid Power – Our Solution ↩︎

- Solid Power’s High Energy, Automotive-Scale All Solid-State Batteries Surpass Commercial Lithium-Ion Energy Densities ↩︎

- Li-ion co-inventor patents glass battery that could upturn auto industry ↩︎

- University of Bayreuth analysing glass battery separators ↩︎

Comments