Even though electric vehicle adoption is picking up speed, some buyers are hesitant because of range anxiety and concerns about lithium-ion battery safety. There’s a lot of money and time being invested into alternative battery tech to address some of those issues and an interesting one popped up recently involving metal-air technology … that could make an EV with over 1,000 miles of range. Is it too good to be true? Let’s explore aluminum-air batteries and whether they’re a game changer or only hype.

Along with green power sources, electric vehicles are an important piece of the puzzle for setting the course towards a net-zero future. The EV market has been growing fast in the last few years. According to the International Energy Agency (IEA), in 2016 the global electric passenger car stock was 2 million, but as of 2020 that topped 10 million. 1

But driving range and range anxiety is still a barrier for some and it’s slowing down EV market growth. Although lithium-ion batteries have been driving a revolution in electric vehicles, we typically see ranges of 300 miles or less, which may not be enough for long trips depending on where you live. And nobody wants to wait for long periods of time while recharging on a road trip or to struggle finding a nearby fast charger. On top of that, there still are some concerns about perceived lithium battery risks like battery degradation from temperature variations, leakage caused by mechanical stress, and overcharge or discharge. 2

These issues have left a door open for researchers and companies around the globe to find better alternative battery technologies, like liquid air, liquid metal, solid-state, supercapacitors … there’s almost a never-ending list. But an approach that may have been overlooked in some parts of the world has been receiving heavy investment in India: aluminum-air batteries.

Al-air batteries date back to the 1960s, but they weren’t considered commercially viable due to concerns around the safety of their electrolyte composition. An engineer and former officer in the UK’s Royal Navy, by the name of Trevor Jackson, started doing experiments with these batteries in 2001, and the belief that aluminum-air batteries were potentially dangerous has taken a different path. 3

Aluminum-air batteries utilize aluminum alloy plates as the anode, a non-toxic, safe electrolyte like potassium hydroxide or even water, and air in the cathode with a catalyst, which can be silver-based. So how does this work? 4 5

Well, if you’re familiar with hydrogen fuel cells, this works in a similar way. Air is sucked into the cathode system containing a catalyst in order speed up a chemical reaction to separate the oxygen molecules from the air. A simple example of a catalyzed reaction is the decomposition of hydrogen peroxide, which undergoes a very slow decomposition under ambient conditions, forming oxygen gas and water.5

2H2O2 → O2 + 2H2O

For example, When we put hydrogen peroxide on a wound you can see the formation of bubbles, which are basically oxygen gas being formed very quickly. This reaction was accelerated by putting the hydrogen peroxide in contact with the wound. The same basic principle is at play in the aluminum air battery. 6

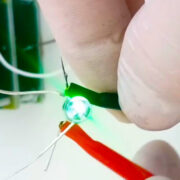

Oxygen is separated from the other components of air by the silver-based catalyst that blocks CO2 from entering into the battery, but it allows O2 to pass through to the electrolyte in order to react with water and produce negative hydroxide ions (OH-). At the anode, positive ions of oxygen (O+) react with aluminum, causing the formation of Aluminum Trihydroxide [Al(OH)3], which is a white powder, and electrons … and it’s those electrons that mean we can generate electricity. When the battery is connected to a load, like a light bulb, these electrons move from the anode to the cathode to give back the electrons lost during the chemical reaction. 4 5

Aluminum is the most abundant metal available globally and isn’t expensive or complex to recycle. On top of that, aluminum-air batteries have a great advantage with weight compared to lithium batteries. Aluminum, which you’re probably already aware of, is extremely lightweight, which makes it a great choice for the anode. The oxygen that’s used in the cathode doesn’t need to be stored since it’s pulled from the surrounding air. This results in a much lighter battery that can give a significant amount of energy to something like an EV. Because of these pros, the technology has been on the radar of some countries as a sustainable solution. 7

As we all know, China is a global giant that provides materials and technologies to most countries around the world, but countries like India have been looking for new alternatives to become independent when it comes to energy storage technologies. Indian Oil Corp, which is the largest oil company in India, has been betting on aluminum-air batteries as a better alternative to lithium-ion. They’ve invested and partnered with the startup Phinergy Ltd. in order to bring this technology to market. 8 9

Although the country has some lithium resources, Indian jungles have large reserves of bauxite, which is used to make aluminum. So it shouldn’t be a surprise that India is one of the top 10 bauxite producers of the world, and they’re trying to become one of the largest smelters of aluminum in the world. 8

So with the pros of being lightweight and having ample material supplies to make aluminum-air batteries, what’s the catch? Nothing’s perfect and neither are these batteries.

One problem is the cost of materials that need to be added to the battery to avoid power dropping. When it comes to cost, aluminum is still very cheap compared to other elements used to build batteries. Aluminum costs $2.55 per kilogram, while lithium and nickel cost $15.75 per kilogram and $18.75 per kilogram, respectively. But one of the other elements you typically use in aluminum-air as a catalyst in the cathode is silver, which costs about $773 per kilogram. 10 11 12 13

Another tiny, little problem that might catch your attention … these batteries aren’t rechargeable. But India Oil thinks they’ve already figured out a solution, which involves making it quick and easy to replace and recycle the batteries.

According to the company, the battery can be replaced within three minutes, and Indian Oil Corp.’s service stations will be used as swap stations. 8

Phinergy raised $60 million from an initial public offering in Tel Aviv this year, and telecommunication companies have tested their energy storage systems as a backup power source for transmission towers and other sites. In addition, the company tested out their tech in an EV, using an aluminum-air battery to charge the vehicle’s lithium-ion power pack that could provide a range of 1,750 kilometers (about 1,000 miles).

To give this some context, a Tesla Model S can get 370 miles with a single charge. Trevor Jackson, who I mentioned earlier, claims that replacing a conventional Tesla lithium battery with an aluminum-air battery of the same weight could get over 2,700 miles. That’s a 7X boost in range, which makes it a little hard to believe, right? 3

Aluminum-air batteries currently have energy densities of about 1,300 Wh/kg and are projected to get up to about 2,000 Wh/kg. And the theoretical energy density of aluminum is 8,100 Wh/kg. That’s about 14X the energy density of commercial lithium cobalt oxide batteries currently on the market, which come in at about 570 Wh/kg.14 10 15 16

Automakers Mahindra and Mahindra Ltd., Maruti Suzuki India Ltd. and Ashok Leyland Ltd. will be running tests for one year in order to evaluate the feasibility of wide-scale use of aluminum-air batteries in India. If things go well and they see enough demand, Indian Oil and Phinergy plan to set up a gigawatt-scale factory to make the batteries in India. 8

But interest in aluminum-air batteries doesn’t stop at cars. The super high energy density, low weight, eco-friendliness and good recyclability has also drawn a lot interest for marine applications.

Yara Marine Technologies created a start-up accelerator program called Yara Marine X earlier this year, aiming to support start-ups pioneering green marine technologies … Green Marine sounds like a Marvel character. Among the several start-ups that applied, Phoenician Energy’s aluminum-air battery impressed the scientists. For six months, Yara Marine X will provide the capital, marketing and networking that Phoenician Energy needs to manufacture and build out aluminum-air batteries. So far Phoenician Energy has built a 4.8 MWh system enclosed in a 20-foot shipping container for marine applications. 17 18

Udi Erell, Founder and President at Phoenician Energy said:

“Al–air batteries have one of the highest energy densities of all batteries, with more than four times the capacity of the conventional lithium-ion battery … In addition, we do not recharge our system onboard, instead, we replace it with a fully charged one, eliminating downtime that would be required for recharging conventional batteries…”17

After the six months of Yara Marine X support are up, Yara Marine may offer a $150,000 investment in exchange for a 10% stake in Phoenician Energy. 18

Although Al-air batteries may have great potential, some of the hype around this has been overblown and I have to get back to the major disadvantages and challenges … like the fact it’s not rechargeable. Once the aluminum is consumed, the battery stops working and has to be replaced. Imagine traveling with your family at night and missing the fact your long lasting battery is almost out of charge. What happens when you run out of juice? Battery-swapping stations wouldn’t be available everywhere. A regular EV could get a tow charge, or a small top up from a portable battery wherever they are from an equipped tow truck. An aluminum air battery would have to be towed to a battery swap station. That’s a big problem. 7

In addition, alkaline electrolytes provide good battery performance for Al-air batteries, especially under high discharge current, which is the case for EVs. But alkaline electrolytes combined with aluminum electrodes tend to be highly corrosive, which is the main problem holding back Al–air batteries. 19

Aluminum-air batteries have a high degradation rate due to aluminum corrosion. While lithium batteries have a 5% degradation after a month of being used, aluminum-air batteries lose 80% of their capacity. And although some techniques have been tested to overcome this drawback, they reduce the power output.

To get around the corroding electrolyte issue, it’s been suggested to use a pump to pump the electrolyte out of the battery while it isn’t used and then pumping it back in when needed. It’s a bit of a brute force solution, but aluminum corrosion can still cause problems by clogging the pumping system. 20

To try and get around this, researchers from MIT have designed a system that utilizes oil pumping. Brandon Hopkins and his research associates noted:

“The oil pushes out the corrosive electrolyte from the surface of the aluminum electrode, which is what stores the energy in the battery.” 21

This approach resulted in a energy loss of just 0.02 percent after a month running the battery. 20

Even though aluminum-air batteries have been in existence for over half a century, they’re still at the developmental stage. Challenges with corrosion, degradation, and non-rechargeable capacity raise serious questions about whether they can be a viable replacement for lithium. The crystal ball prediction for the future Al-air battery market is still cloudy. There’s still a lot of investment and research needed to overcome the drawbacks.

- Trends and developments in electric vehicle markets ↩︎

- Solid-State Batteries Advancing Toward Promise of Fast Charging, Long Life, Safer Use ↩︎

- Al-air: a better battery for EVs? ↩︎

- An electric vehicle battery that doesn’t need electricity for charging ↩︎

- Aluminum Air Battery: How Do They Work? (Plus DIY) ↩︎

- How does a catalyst make Hydrogen Peroxide’s decomposition quicker? What is actually happening? ↩︎

- Aluminum-air battery technology for electric vehicles ↩︎

- A Major EV Battery Bet for India Is on Aluminum Over Lithium ↩︎

- An electric vehicle battery that doesn’t need electricity for charging ↩︎

- Aluminium–air battery ↩︎

- Aluminum Price Today ↩︎

- Nickel Price Today ↩︎

- LITHIUM AT THE LME ↩︎

- What are some advantages of Li-ion batteries? ↩︎

- Fuji Pigment Aluminum Air Battery Ready For Commercialization This Spring – Recharge It With Water ↩︎

- Lithium-ion battery ↩︎

- Phoenician Energy’s aluminum-air batteries win in Yara Marine’s accelerator program ↩︎

- Aluminum-air battery innovator wins spot in Yara Marine X program ↩︎

- Energy Materials ↩︎

- A Solution to the Aluminum Air Battery Issue ↩︎

- Aluminum-Air Battery Corrosion Oiled Away ↩︎

Comments